Energy efficiency coefficients COP, EER, SCOP and SEER and their importance in choosing a heating system

Efficiency (coefficient of performance)

Efficiency (efficiency factor) reflects the ratio of energy costs for heat generation to useful heat used to heat a home. A rough calculation of the heating efficiency is carried out according to the formula η \u003d A / Q, where A is the energy consumed, Q is useful heat. But, it does not take into account the many nuances that should be taken into account. Any heating system uses consumables (fuel or electricity) that provide heating of the coolant. Knowing the calorific value of different types of fuel or the consumption of electricity for heating a unit area, it is possible to compare the energy potential of the heating system. The comparison table shows the approximate calorific value and the cost of the most efficient energy sources used in heating:

| Energy source | unit of measurement | Unit cost, UAH | Specific heat of combustion, kW |

|---|---|---|---|

| Electricity | 1 kWh | 1.7 | one |

| Natural gas | 1 m3 | eight | 9.0 |

| wood pellets | 1 kg | 3 | 4.5 |

| Diesel fuel | 1 l | 28 | 11.8 |

The efficiency of a gas condensing boiler is 100%+, a conventional gas boiler is 90 - 92%, for a diesel fuel boiler it will be about 90%, for a solid fuel pellet boiler it will be 75 - 80%, and an electric boiler will give all 98%. Simple calculations show that despite the high efficiency and calorific value of an electric boiler, the cost of the energy source used is too high for it to become a priority equipment for heating a house. Diesel fuel and natural gas share the 2nd and 3rd places in terms of heating efficiency, and wood pellets turn out to be a more profitable option. And the installation of a gas boiler is associated with certain conditions and approvals, while safe operation requires careful monitoring.

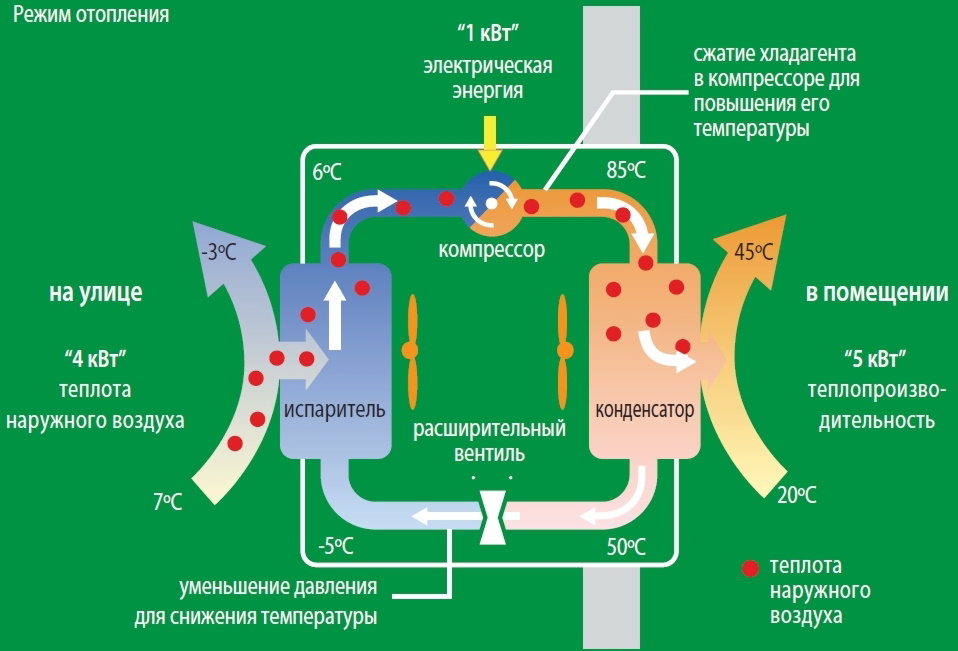

Today, among the owners of private households, the popularity of heating is gaining momentum using split systems with a "winter" heating function in severe frost, as well as heat pumpsusing heat transfer from the street to the room. It should be borne in mind that the efficiency of such heating systems does not have a fixed value and very strongly depends on the temperature of the air in the street, from which the system receives its thermal potential.

Another important aspect of energy efficiency is to take into account heat losses in the premises, which cannot be avoided in practical operation. Useful heat leaves through walls, window frames, ceilings, floors, and is also spent on infiltration, which is an uncontrolled air exchange that occurs through gaps in building structures invisible to the eye. In addition, controlled heat losses through the ventilation system must also be taken into account. The amount of heat loss depends on the temperature difference between indoors and outdoors and increases significantly in severe frost. There are many online calculators on the net that will help determine the value of irretrievable heat loss. Without going into the details of mathematical formulas, it is possible to calculate the approximate value of heat losses in rooms of different sizes, taking into account the thickness and types of different wall materials and finishing materials.

Calculation of basic cooling coefficients EER and heating COP

When buying an air conditioner or heat pump, be sure to pay attention to such an important characteristic as electricity consumption. In the user manual and on the label of these thermal converters, parameters such as ERR and COP are indicated, which are generally recognized international indicators used in all countries to eliminate confusion with the marking of equipment. These coefficients are conditionally comparable with the efficiency of fossil fuel heaters, but are not estimated as a percentage, but as a regular number. The higher the value of the coefficient, the better, because you will spend less energy per unit of work. The Energy Efficiency Ratio (ERR) is the instantaneous performance index of the device when operating in cooling mode. It is calculated as the ratio of the cooling capacity of the QX appliance to the total power input Ncons.:

EER= QX/Ncons.

The heating energy efficiency coefficient COP(Coefficient of Performance) displays the heat index equal to the heating power QT divided by the consumption power Ncons.:

COP= QT/Ncons.

Simply put, these coefficients show the amount of heat and cold produced by an air conditioner per unit of electricity consumed in a given specific period of time. For domestic air conditioners and split systems, the EER value ranges from 2.2 to 3.5, while the COP indicators are slightly higher: from 2.4 to 4. This is due to the fact that the operating equipment generates more heat than cold, which has become a reason for unscrupulous manufacturers to use marketing tricks. They began to write on their products only a higher value of the COP coefficient, not indicating the EER at all. Let's give an example of specific values indicated on the plate to the device. Under the same conditions, the air conditioner can have the value of the coefficients EER - 3.2 and COP - 3.6. This means that for 1 kW of electricity consumed, it will produce 3.2 kW of cold or 3.6 heat.

|

Both indices are calculated for the nominal mode under standard conditions, which allows you to quickly assess the efficiency of the equipment for cooling or heating the room. At the same time, the values were measured at the maximum load of the equipment, and as the basic conditions for measuring the energy efficiency coefficients according to the ISO 5151 standard, the ambient air temperature was taken to be +35 °C for cooling mode and +7 °C for heating mode.

Seasonally adjusted: SEER and SCOP coefficients and valid energy efficiency classes

The system for determining the energy efficiency of equipment, based on the coefficients EER and COP, which was in effect until 2013, until some time suited everyone. In accordance with it, each numerical range of the coefficient corresponded to one of the 7 letters of the energy efficiency class (from A to G):

|

But with the advent of the EU directive ErP (Energy related Products), aimed at the priority use of renewable energy sources and strict control of energy conservation, a revision of the rules of the game was required.

According to the new classification, classes are now distributed in the range from A to D, and in the economical "green" zone there are now devices limited to the letters A with and without "pluses" and B, which makes 5 classes:

|

The addition of the letter S (season) to the abbreviation of the coefficient indicates that now the current and more accurate parameter is the assessment of the efficiency of the device during one season, and not, as in the cases of COP and EER, pointwise at the moment. The new energy efficiency classification system based on seasonal (average annual) SEER and SCOP coefficients made it possible to take into account the operation of equipment in different climatic conditions. Since the calculations of these coefficients are carried out for different operating temperatures, the obtained values more reliably reflect the efficiency of the air conditioner. The changes that have now come into force distinguish 3 geographical zones in Europe with a warm, temperate and cold climate, which should be taken into account when operating in heating mode:

|

The calculation conditions also reveal the hitherto hidden advantages of models with inverter control. which continuously operate at partial load, saving up to 40% on operating costs due to reduced power consumption.

The main indicator of seasonal heating costs is such a characteristic as degree-days of the heating period, which is calculated by the formula:

GSop \u003d (tVN - tOP) * ZOP,

where tVN denotes the air temperature maintained in the room, tOP is the average outdoor temperature during the heating period, ZOP is the duration of the heating season (OS). For calculation, we take the temperature in the room equal to 20 °C, and the duration of the heating season is calculated by the days when the temperature outside does not exceed +8 °C. The initial indicators differ for different cities of the country and depend on their geographical location on the map.

In our climatic conditions, we can consider the difference in heating costs using the example of such cities as Kyiv, Lvov and Odessa:

| Cities | Average outdoor temperature during the cold season | Length of the heating season | Average daily temperature OS | Degree-day OS (at tHV = 20 °C) |

|---|---|---|---|---|

| Kyiv | -5°C | 176 | -0.6°C | 3626 |

| Lviv | -3°C | 179 | 0 °C | 3580 |

| Odessa | -1°C | 158 | +1.7 °C | 2891 |

Table indicators show that the difference in operating costs for heating in the middle lane is 25% more than in the south of the country.

What is more profitable to heat and the payback of thermal equipment

The consumable part of any heating system can be divided into the following components, which often determine the choice of the type of equipment:

- initial one-time costs for the purchase, installation of equipment and arrangement of a special boiler room;

- operating costs for the heating season and maintenance.

- the need to connect to the gas network and the bureaucratic red tape associated with all approvals; complexity of installation and operation of the device.

One-time costs for the purchase and installation of thermal equipment

It should be taken into account that when buying a heating boiler, one should take into account not only the cost of the main equipment, but also the costs of piping, laying a chimney, and in some cases, the arrangement of a separate room (boiler room). In this regard, electric boilers, which do not require additional costs during commissioning, have a definite advantage.

Of particular note is the problem of bureaucratic red tape associated with connecting gas boilers. Before installation, you need to develop a project that cannot be done on your own, for which you should contact a specialized design organization that has licensing authority for this. All technical conditions and details of the project must be agreed with the relevant gas service authorities, and in the future, all installation work must be carried out by certified specialists. A contract must be concluded for the individual supply of gas for heating needs. After passing through "all the circles of hell", you need to get the final conclusion of a gas office specialist that everything is done correctly and the boiler can be used. It's all long, troublesome and expensive, so before getting involved in this story, it makes sense to think, but "is the game worth the candle"?

Solid fuel boilers, regardless of the type of consumable resource, have another problem. Loading fuel has to be done manually, and it is very physically difficult. The bunker supply helps a little, but still no one canceled manual labor. In fact, when choosing a solid fuel boiler, you need to prepare for the fact that you will be a fireman in your own home boiler room. And it’s good if someone can replace you when you are sick or feel unwell.

Heat pumps that use external heat are used not only to heat the house, but also to supply it with hot water. Ground-to-water heat pumps have a high energy efficiency coefficient, good heat transfer, but require complex and costly drilling and communications work. Usually, the commissioning of such equipment costs more than their cost, so if you think that it is better to invest in installation work in order to save on operation, then this is a good solution. Thermal water-to-water technology, using the heat of geothermal sources, also requires the cost of laying water intake communications and maintaining pumps, but it digests more electricity than ground models and, accordingly, the return coefficients are even better.

Modern air-to-air and air-to-water heat pumps also have the highest class A ++ energy consumption coefficients, so the financial costs are on average 2 times less compared to gas heating, and 4 times less compared to electric heating. Air-to-water heat pumps are optimal solutions with a minimum investment in installation work, but are very dependent on the outside temperature. They show their best potential in surface heating systems (underfloor heating and walls) requiring a temperature in the heating system between 30 and 35 °C.

|

Heated air conditioners and air-to-air heat pumps are not very productive as a full replacement for heating technology for radiator heating. The installation costs of such devices are the lowest, and the cost of buying a heated air conditioner or pump is only 1.5 times higher than a heating boiler, so this technique pays off pretty quickly. But based on the specifics of the operation of this equipment, it is better to use it in warm regions with a mild climate.

Operating costs and payback period

In addition to the source of thermal energy, which serves as a consumable, consumption during the heating season will be affected by:

- characteristics of the building: its area, geometry, and even direction to the cardinal points;

- building energy efficiency. This, in simple terms, is the quality of thermal insulation of premises: the better they are insulated, the less energy is required to heat them;

- climatic zone. We discussed this aspect earlier. It is quite obvious that the higher the temperature "overboard", the less you will spend on heating;

- seasonal heat conversion factor (see above);

- service costs.

Of course, the main criteria for choosing thermal equipment will be its cost and approximate costs during the heating season, taking into account existing market prices.

The cheaper it is to heat a house: calculation table

To estimate the cost of heating costs in the cold season, an example of heating a well-insulated private house (40 cm gas block + 10 cm foam plastic + 20 cm roof insulation + 10 cm styrodur on the floor, double-glazed windows) of a house with a total area of 300 m2 was taken. Among the applicants for the best heating system are an electric, gas and solid fuel pellet boiler with a hopper, as well as an air heat pump with an internal water circuit. All heating equipment has a power of 15 kW, which corresponds to the total heating area. According to the conditions, the calculation was carried out for a temperate climate with an average daily temperature of -5 °C for the entire season and a heating season duration of 150 days.

| Type of thermal equipment | Cost of thermal equipment, c.u. | Energy cost, UAH | Calorific value of fuel | Volume of energy carrier for the heating season | Costs for the heating season (150 days, average daily t = -5 °C), UAH |

|---|---|---|---|---|---|

| electric boiler | up to 1000 | 1.7 per kW | 1 kW | 19030 kW | 32351 |

| Gas boiler | before 2000 | 8 per m3 | 9 kW/m3 | 2645 m3 | 21160 |

| Solid fuel pellet boiler | up to 3600 with bunker | 3 per kg | 4.5 kW/kg | 5000 kg | 15000 |

| Heat pump, COP 3.0 | up to 6200 | 1.7 per kW | 3 kW/1 kW | 7350 kW | 12495 |

As the table shows, in Ukrainian realities, the battle for the most affordable heating option, based on the operating costs for the season, is won by the heat pump, and the solid fuel boiler is closest to it.

If you are not afraid of the long and thorny path of collecting the necessary permits and "going through the throes", then the obvious choice in terms of economical operation at current energy prices is a gas boiler. And in terms of energy efficiency, a more modern and environmentally friendly heat pump “breathes in the back”.

The lowest price of an electric boiler costing about $1,000 is in practice offset by heavy costs due to the high and ever-increasing electricity tariff (see above). Yes, it will have a quick payback (1 - 2 years), but the expediency of buying at high heating costs is justified only when there is no gas supply in the house, it is impossible to install a solid fuel boiler, or simply there is no money to buy a heat pump ($6,200).

The cost of a gas or solid fuel boiler (from $ 1,000 to $ 2,000) is a “golden mean” in terms of initial costs, installation and operation. A heating boiler is a time-tested equipment with high calorific value, which can fully provide households with heat and hot water all year round. And he also has the advantage that the boiler is appropriate in any climate. The average payback period for these thermal appliances depends primarily on the area of heated premises and is 6-10 years.

Split systems with heating function and heat pumps are a good means of backup or additional heating in the middle lane, as well as a good option for heating housing in the southern regions of the country. The payback period for such devices is 2-4 years for air conditioners and 5-8 years for a heat pump. This is a very short period compared to the long and trouble-free life of this equipment, which is tens of years.

More progressive, but still not very common, are electric heating systems based on renewable energy sources - the sun and wind. Here, much will depend on the wind rose in your area and the number of sunny days per year. Moreover, such equipment is quite expensive and will not pay off soon, despite the “free” natural resources.

If there are interruptions in the supply of gas and electricity in the building area, then it is worth considering the option of combined heating, using several heating sources that can replace each other during an emergency period.

Articles, reviews, useful tips

All materials