How to Choose Snow Chains for Your Car

We independently test the products and technologies that we recommend.

Anti-skid chains refer to both actual chains on wheels and devices of other structural designs: belts, bracelets, anti-slip tapes. First, it is important to understand the difference between the mentioned options.

1. Classification by Types

Anti-skid devices in the form of chains with characteristic links have become the most widespread. Chains need to be put on the drive wheels of the vehicle, and in all-wheel-drive vehicles, they are installed on the front or all wheels. Chains provide high traction properties, are distinguished by excellent reliability and durability. However, if a chain breaks, it can damage the body surfaces and transmission of the car.

Belts and bracelets are safer for the car's body elements, easier to maintain, and simpler to store. However, such devices are inferior to chains in terms of traction characteristics, reliability, and durability. Belts and bracelets differ in the width of the working area — this is clearly illustrated in the image below.

Anti-slip tapes or tracks imply a different principle of action. Essentially, they are a spiked mat that is placed under the stuck wheels of the car. Tracks help the wheels find support on very slippery or loose surfaces, whether it be deep snow, wet grass, sand, or mud.

2. Manufacturing Materials

Conditionally, all types of anti-skid devices can be divided into two large groups:

- rigid — made of hardened steel, less often titanium; used for moving through deep snow and most effective on ice;

- soft — equipped with plastic, rubber, or polyurethane snow grips.

Metal rigid chains "perform" in the most unfavorable conditions, however, they significantly wear out the tire tread when moving on a hard road surface.

Soft nets on wheels facilitate overcoming snowy areas but are practically useless on ice. Moreover, in the cold, rubber loses its elasticity, which complicates the installation of such products on wheels. Travel speed with them — up to 80 km/h.

Both classic chains and belts (bracelets) are made of metal. The difference lies in the fact that bracelets are usually fastened with a textile strap that is passed through the holes of the wheel disc. The fabric strap does not damage the disc surfaces, while the steel links directly contact the snowy or icy road.

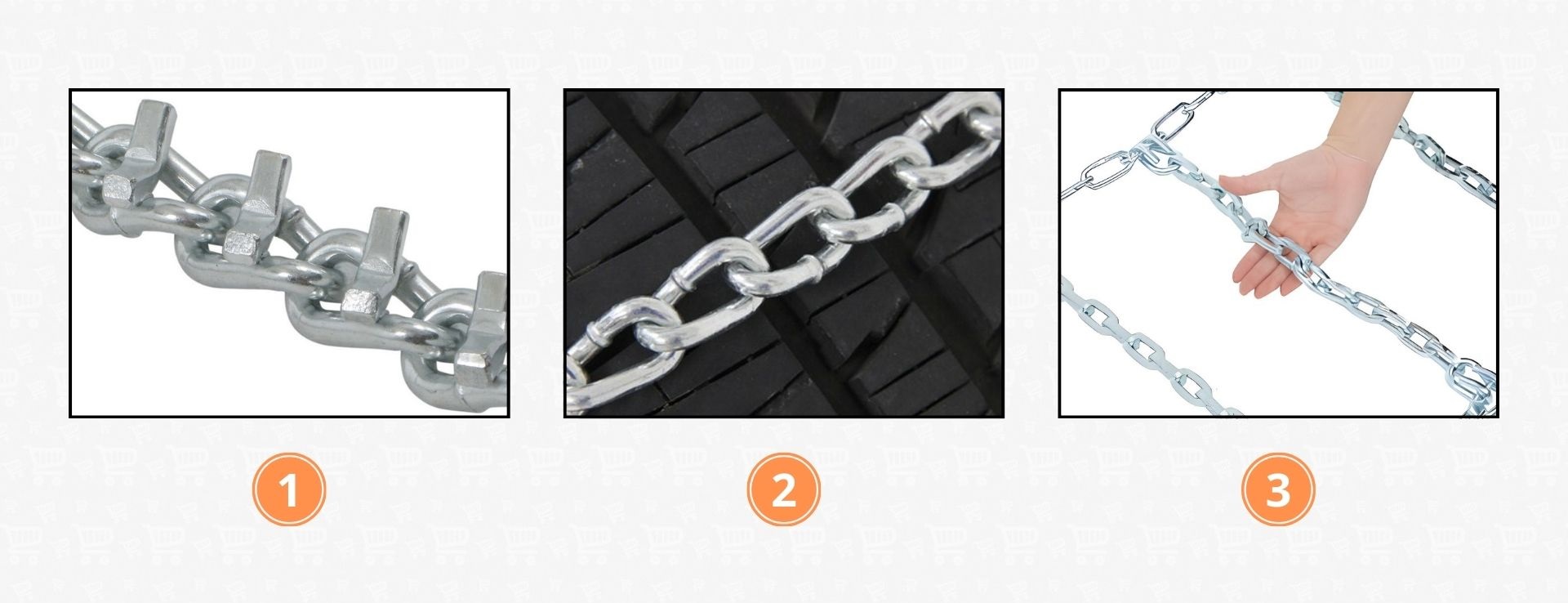

3. Weaving

The "ladder" or "step" pattern is more convenient in terms of installation and provides good traction potential in a straight-line trajectory. In side skids and ruts, the "ladder" is ineffective, and when the wheel rotates, it can cause jerks and slips, which potentially harms the car's transmission.

Maximum efficiency is achieved with diamond-shaped chain weaving (in the form of honeycombs). This pattern provides less traction force, but it optimally counteracts side skids and follows the shape of the wheel. In the "honeycombs," the chains are connected crosswise, forming a kind of web. Thus, when in contact with the road, many more links are in the contact zone, increasing the vehicle's passability.

2 – And with a diamond pattern — resemble honeycombs.

Textile chains or "snow socks" are noted separately. They are suitable for short trips in moderate conditions but are significantly inferior to metal chains in terms of grip properties. These "socks" look like a cover on the wheel.

4. Shape and Height of Cells

Anti-skid chains can have different shapes and differ in cell height. Most often, chains with ordinary twisted links are found — a kind of universal option for conquering any snowy roads. In deep and loose snow, chains with rectangular (square) links perform better, but movement with them is less comfortable. Finally, chains with special ice picks hold firmly on icy surfaces. The latter option cannot be used on regular roads, as chains with additional "spikes" have a very rough impact on the road surface.

Chains are classified by cell height as follows:

- 6 – 12 mm — for passenger cars;

- 12 – 16 mm — for crossovers and SUVs;

- from 16 mm — for trucks and special equipment.

Such division is quite conditional, as in practice, the chain is selected by cell height based on the minimum clearance in the car's wheel arch space. For passenger cars with low-profile tires, chains with link sizes of about 6 – 7 mm will do, and for SUVs with minimal clearances behind the wheels — chains with cell heights of 9 – 12 mm. In complex cases, you can resort to specialized chains installed on the wheel bolt on the outside of the disc — none of their parts touch the inner wall of the tire.

5. Size Grid

Often, chains, belts, and bracelets are made universal and fit a wide range of tire sizes. In the basic version, they are selected for a specific tire diameter. A narrower choice is possible by KN classes:

| KN Class | Tire Size |

|---|---|

| KN-40 |

|

| KN-50 |

|

| KN-60 |

|

| KN-70 |

|

| KN-80 |

|

| KN-90 |

|

| KN-100 |

|

| KN-110 |

|

| KN-120 |

|

| KN-130 |

|

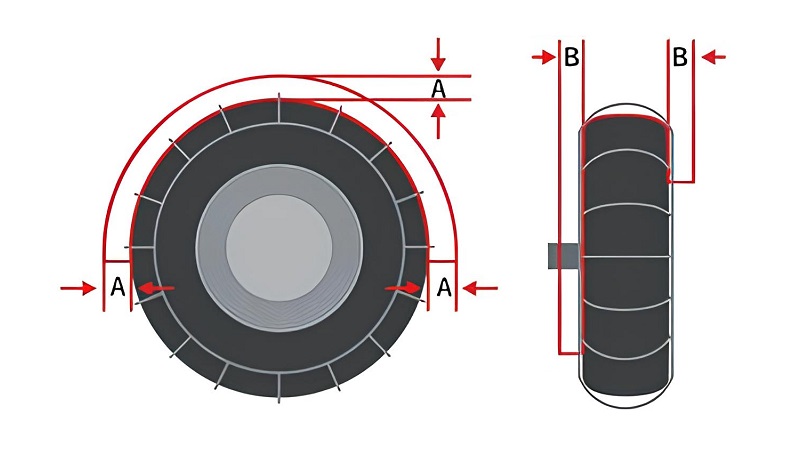

Tire sizes are not the only parameter by which anti-skid chains are selected. According to the specifications of the American Society of Automotive Engineers (SAE), three groups of chains are produced:

- S — non-reinforced chains for passenger cars with limited space in the wheel arches (no more than 37 mm between the top of the tire tread and the arch, no more than 15 mm between the inner side of the tire and the car body elements);

- U — regular or reinforced chains for cars with sufficient under-wheel space;

- W — chains for large vehicles and large wheels.

distance A — no more than 37 mm between the top of the tire tread and the wheel arch,

B — no more than 15 mm between the side of the tire and the car body elements.

6. Tension

Mostly, chains are tensioned manually. That is, they need to be installed on the wheels, drive 10 – 20 m, get out and tighten again. As the chain settles on the wheel during rotation, its extra links need to be pulled through the corresponding ratchets. However, there are separate auxiliary tensioners to help with the installation of such chains.

In models with automatic tensioning, the chain tightens itself on the wheel with the start of movement, eliminating the need to stop and tighten it manually. There is also no need to tighten belts and bracelets — they are a priori tightened on the wheel during installation.

Finally, note that chains are usually sold in pairs: in quantities of 2 pcs., less often — 4 pcs. Belts and bracelets are often presented in sets of 4 to 10 pcs., but can also be available individually. Tracks are supplied in quantities of 2 – 4 pcs., and they can be connected to each other into long tapes.