How to choose an angle grinder

We independently test the products and technologies that we recommend.

1. The grinder is a universal tool

Although the angle grinder is called a grinding machine, it is in fact a truly universal tool that is far from limited to grinding alone. In addition to grinding, the angle grinder can be used to cut metal, stone and ceramics, clean surfaces from rust, remove layers of paint and varnish materials and perform other work, including such specific ones as chasing walls for wiring. Therefore, when choosing an angle grinder, you should take into account the features of the work that you plan to perform with this tool.

2. Main criteria for choosing a grinder

One of the key characteristics of the angle grinder is the power of the electric motor. The higher it is, the more complex tasks can be performed. A more powerful motor increases the productivity of cutting, cleaning or grinding and allows the grinder to be used for work with significant loads.

- Up to 1 kW — suitable for many tasks, including work in a home workshop. Models with such power can be used for cutting rolled metal, cleaning seams on welded structures, grinding small areas, etc. Tools of this class are sometimes so compact that they allow you to work with one hand.

- 1.5 – 1.8 kW — angle grinders with such power are considered middle-class tools. They are the most versatile, as they allow you to confidently perform a variety of work: from cutting metal to cleaning and grinding large surfaces.

- More than 2 kW — best suited for professionals who often use angle grinders in their work. Such powerful tools allow you to quickly grind large surfaces, cut thick metal and cut grooves in brickwork.

The second important parameter when choosing an angle grinder is its size - the maximum size of the equipment that can be installed on the tool spindle. This characteristic determines which cutting wheels, grinding discs and wire brushes can be used during operation.

- Up to 125 mm — angle grinders designed for use with discs up to 125 mm in size are the least powerful, but at the same time the lightest and most compact. They are suitable for cutting thin sheet metal and cutting profiled rolled products with thin walls. Such tools are often used when performing work related to welding small metal structures, for cutting metal blanks, forming chamfers and cleaning welds.

- 150 – 180 mm — tools designed to work with equipment of this size allow you to make deeper cuts and perform grinding work faster. The largest range of replaceable attachments is produced for this size: solid circles with coarse abrasive, metal discs with diamond coating, grinding wheels with "petals" of different grain sizes, metal round brushes, etc.

- More than 220 mm — angle grinders for large discs with a size of >220 mm are used primarily by professionals in industries such as construction or metalworking. The large size of the equipment allows for quick, wide-ranging cleaning and grinding of surfaces, as well as deep cuts when cutting metal, concrete or building blocks.

Like other modern power tools, angle grinders come in corded and cordless varieties.

- Mains-powered angle grinders are usually more powerful and cost significantly less (compared to cordless angle grinders of the same size). They are better suited for work in a home workshop, in production and on construction sites where you can plug the tool into a household electrical outlet or connect to a generator.

- Cordless angle grinders are mobile and self-contained. Battery power allows you to cut, clean and grind when working on objects not connected to the power supply network, as well as work in places where it is inconvenient to pull an extension cord. But it should be noted that the price of a cordless angle grinder complete with a capacious battery is significantly higher than the cost of a conventional corded angle grinder.

3. Minor, but also important details

Many modern angle grinders boast additional functions and mechanisms that make work easier or faster. They are worth paying attention to when choosing a grinder.

- The speed controller for setting the optimum rotation speed of the tool and constant electronics that automatically stabilize the set speed allow you to precisely adjust the tool to perform a particular task.

- A safety (disengagement) clutch, which provides protection against kickback when the disc jams, and electronic protection of the motor from overheating are important for a tool that is planned to be used for long-term non-stop work or with heavy loads.

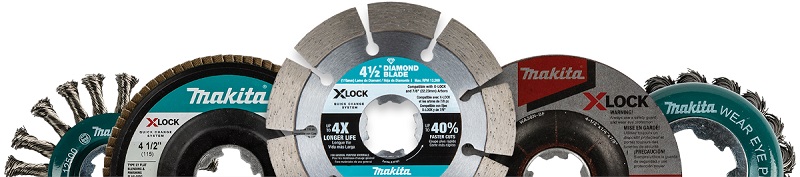

- The keyless disc replacement mechanism saves a lot of time when performing work related to frequent replacement of equipment on the grinder. But note that some of the most "advanced" fasteners (like the X-LOCK mechanism) require the use of special discs and circles - more expensive and less common.

4. Individual requirements for the grinder

When choosing an angle grinder, you should also consider the design features of the tool that affect user comfort. In particular, it is worth paying attention to where the start button is located (on the rear handle or on the left side of the body near the gearbox) and what its dimensions are (a long button can be more convenient, as it allows you to change the position of your palm). For some tasks that involve long-term work without stopping, it would be nice if the angle grinder had a start button lock. Other design features that make using an angle grinder more convenient include the ability to rotate the rear handle 90° left and right and the presence of a mount that allows you to adjust the position of the protective cover without using keys and screwdrivers.

It is also worth keeping in mind the specifics of the work that you plan to do with the grinder. For example, when processing brick and stone, the quality of protection of the tool from dust is of fundamental importance. When using an angle grinder in projects involving a large number of small operations and frequent switching on and off of the tool, a grinder with a motor brake will come in handy, quickly stopping the rim when the button is released. If you need to work for a long time without stopping to replace the battery, then you should buy a grinder with a large battery and a brushless motor, which uses the battery charge more economically (by 15% - 20%). And sometimes it is worth paying attention even to such nuances as the size and shape of the gearbox housing, because it may simply not fit into the angles of metal structures and other hard-to-reach places.

5. The difference between expensive and cheap angle grinders

Some design features and the overall quality of grinders cannot be described in the form of technical specifications or displayed using the selection points in our power tool catalog. That is why we wrote a separate article , “What is the difference between an expensive grinder and a cheap one?”, dedicated to the pitfalls of choosing an angle grinder. It reveals some interesting points related to the quality of the parts and units “under the hood” of the grinder: in the engine, gearbox, electronics, etc.

6. Conclusions and recommendations

Among the thousands of different models of angle grinders available for sale in online stores, it is unlikely that you will find even one that will suit absolutely all users. Therefore, every craftsman who wants to buy an angle grinder should answer himself:

- What tasks is the tool intended to be used for?

- How often, under what conditions and with what load will the grinder work?

- What features or design characteristics will help you get the job done faster and with less fatigue?

The correct answers to the questions posed will help you choose a grinder that will cope with its tasks, but at the same time not overpay for unnecessary functions or excess power.

Articles, reviews, useful tips

All materials