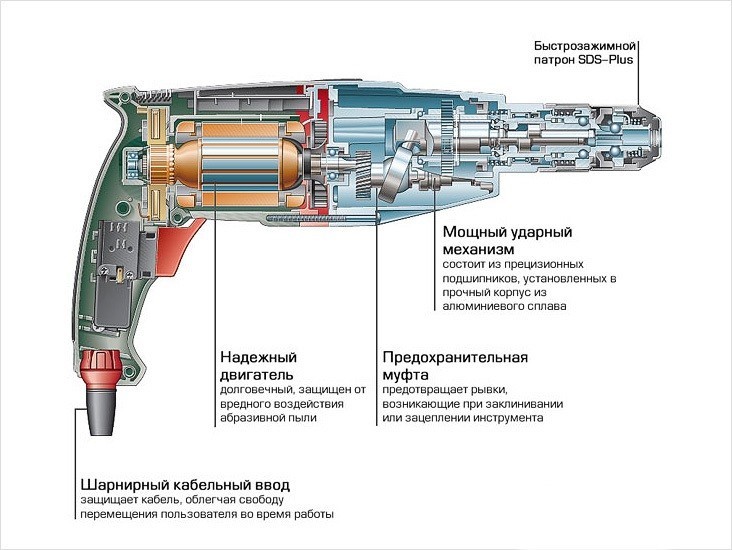

Perforator device

Perforator design

Regardless of the modification and additional functions, each rotary hammer has electrical and shock-mechanical parts. The electrical part contains the following main elements:

- Electric motor.

- Reducer.

|

| Perforator scheme |

The shock-mechanical part includes:

- Impact mechanism.

- Safety clutch.

- Cartridge.

Electrical engine

Impact power tools can have the following types of location of the electric motor:

- Horizontal. Most often, these are light devices for domestic use. Due to their light weight, you can work for a long time without much fatigue in your hands. For example, Makita HR2470 Price from 5 689 up to 10 111 ₴ is perfect for installing foam insulation, assembling furniture or fixing suspended ceilings. However, there are exceptions to the rule. For example, the model Metabo KHE 96 600596000 Price from 30 799 ₴ has a horizontal engine, but it weighs as much as 12 kg. It is worth noting, however, that due to this arrangement of the drive, devices of this type have a poor engine cooling system, which can cause it to overheat.

|

| Device with horizontal drive type |

- Vertical. Here, instead of a rolling bearing, a crank mechanism is installed, which allows you to increase the amplitude when hitting the striker. Thanks to this, the blow becomes stronger, which means that the chiselling work will be done faster. Also, the advantage of the vertical arrangement of the engine is good cooling and low vibration. Of course, such units are not light and you won’t work with them for a long time, but they allow you to perform serious construction work, such as installing air conditioners (you need to make a through hole in the wall). For example, the model DWT BH-11-28 BMC is able to satisfy both domestic and industrial needs.

|

| Vertical drive arrangement |

Hammer hammer mechanism

All modern rotary hammers have an electro-pneumatic type of percussion mechanism. It can be in two versions:

- Rolling bearing (drunk). The rotation from the engine is transferred to the rolling bearing (1 in the figure below), which in turn starts to move the piston (2). Between the piston and the impactor is a small space filled with air. In this space, pressure is created, under the influence of which a blow to the striker occurs. The impact force in this case is less than 5 J, therefore this impact mechanism is inherent in compact models with a horizontal engine.

|

| Rolling bearing layout |

- Crank mechanism. With this scheme, the crank (1) is parallel to the piston sleeve and rotates on the gear. Thanks to this arrangement, the impact force on the striker increases and in powerful professional models it can reach 20 J. Such an impact force is very useful when dismantling concrete and brick walls, foundations, as well as punching holes in concrete septic tanks.

|

| Crank layout |

Vibration protection

Manufacturers of all impact devices try to reduce the level of vibration transmitted to the user by using various structural inserts. So vibration protection is divided into two types:

- Active. This type of vibration protection is also called ATS. It consists of two counterweights placed in the mechanics case, interconnected by a spring. This design dampens some vibration, but does not completely eliminate it. Also in the handle of the unit at the connection with the body of the electrician, hinges and a spring are installed that reduce recoil. Usually active ATS is installed on powerful models.

- Passive. This protection is available in all models, and it is the usual rubber pads on the case, which additionally prevent hands from slipping. Passive protection dampens vibration relatively little.

Safety clutch

This part of the unit protects the motor from current overload, and also prevents injury to a person during strong kickback when the chisel is jammed in the hole. In devices there are such couplings:

- Friction. They are two small discs, close to each other. When the working body is jammed, the disks disperse, sliding relative to each other. When this occurs, the cartridge is disconnected from the electric drive, preventing the combustion of the latter.

- Spring-cam. Here are two hemispheres similar to clutches, but on the surface they have teeth. When the device is jammed, the hemispheres slide and snap with teeth. That is why the user hears a characteristic crack.

Cartridge

There are three types of percussion cartridges:

- Key. This cartridge is a sleeve with toothed fingers (cams) and a turnkey hole. Using the key, the fingers are spread, then the drill is inserted into the sleeve and then the cams are tightened with the same key until they stop. This chuck is convenient in that you can use drills with different shank diameters.

|

| Bit key holder |

- Quick release. This type of cartridge is installed on 90% of all models. It also has three jaws and can be made up of one or two clutches. However, there is no turnkey connector. How to use a rotary hammer with such a cartridge? It is enough to pull the ring (coupling) towards the housing, insert the drill and turn it so that the grooves of the drill enter the sleeve, and release the ring. Thus, changing a drill in a keyless chuck is much faster than in a key one.

|

| Quick clamp |

- SDS. Inside the sleeve there are four or five slots for fixing the shank of the bit and drill. The most common quick-clamping types are SDS max and SDS +. Their difference is that they are designed for different diameters of drill shanks: SDS plus for diameters from 8 to 12 mm, and SDS max from 18 mm and above. SDS + is used in power tools for household needs, such as drilling fasteners for shelves, cleaning walls from old tiles and other work. And SDS max is used in a professional tool for serious work related to chiselling concrete structures.

|

| Chuck SDS+ |

Additional functions

Different models of rotary hammers may have additional functions applicable to certain types of work:

- Depth limiter. This is a metal spoke fixed on the body along the working body. It allows you to set a clear drilling depth for specific fasteners. For example, such a limiter is very useful for assembling furniture, or drilling for “quick installation”, where the depth of the hole must ideally match the length of the dowel.

- Reverse. The reverse rotation function is necessary to release the drill stuck in the hole. Devices with this function can be used as a screwdriver for screwing / unscrewing fasteners.

- Dust removal system. A dust collector is attached to the bottom of the unit, which allows to reduce pollution in the room. If you want to avoid cleaning the room after “percussion-drilling” work, then a model with a dust collector is your option.

- Automatic speed control. The design of the device is equipped with an electronic sensor that automatically adjusts its power to achieve the optimal speed of the drill, depending on its diameter, as well as the hardness of the material. Thus, the rotary hammer itself increases the speed and power when it is necessary to drill hard concrete and vice versa reduces them when a relatively soft material, such as wood or brick, comes across.

How to work as a perforator?

Impact drilling machine can work in several modes:

- drilling. First, turn the mode dial to "drilling" — indicated by the drill icon. Check the idle speed — there should be no knocks and crackles. Then rest the drill on the point you plan to drill, and gently press the start button to start the process. The pressure on the device should not exceed five kilograms, so do not press hard. It is necessary to remove the working body from the drilled hole during rotation, otherwise there is a possibility of it getting stuck.

- Drilling. On the case it is indicated by the icons of a drill and a hammer. As in the first case, it is necessary to gently press on the unit. During operation, you can not change the position of the drill so that it does not warp.

- Hit. This mode is used for chiselling concrete and brick, as well as chasing grooves for wiring or pipes. Set the adjuster to the hammer position. Rest the chisel in the material and start work. It is worth noting that when gating, you can slightly change the angle of the blade to achieve the desired direction.

What you need to know about the device and the principle of operation of a modern refrigerator.

During the heating season, hot batteries become real "eaters" of moisture.

One monitor is good, but two is better.

Maximum image quality in the smallest form factor.

We broadcast the image from the laptop to the TV via cable and "over the air".