Universal soldiers: TOP-5 welding semi-automatic inverters

We independently test the products and technologies that we recommend.

In the summary table, the indicators of semi-automatic inverters presented in the review are available for comparison. In the catalog of the same name, you can choose your own welding machine.

| King-tools.com.ua | 8 955 ₴ | To Store |

| Palladium.ua | 10 882 ₴ | To Store |

| Tviy-Dim.com | 11 311 ₴ | To Store |

| Болгарка.укр | 11 481 ₴ | To Store |

| Mobitek.com.ua | 10 781 ₴ | To Store |

Kaiser Welding welding machines combine high productivity and reliability in one bottle, and also take their toll on a democratic pricing policy. An excellent example of this is the MIG/MAG-265 universal unit.

The model is used for manual arc welding with electrodes (MMA) and work with copper-plated or flux wire with a cross section of 0.6-1 mm in semi-automatic mode (MIG/MAG). The welding current range of the device "floats" in the range from 30-40 A to 265 A. When welding with the highest current for 6 minutes of continuous operation of the device, it is necessary to lay 4 minutes. "smoke break". If the current is lowered to 200 A, the frequency of switching on the Kaiser MIG/MAG-265 increases to 100%.

The welding current value is transmitted by the device on a digital mini-screen in real time (only directly during welding). Handles for changing amperage and voltage, wire drawing speed, inductance peacefully coexist with it. Also, overload light bulbs are placed on the front panel of the device and "+/—" terminals are displayed along with a 3-metre-long euro sleeve (the device is initially equipped with such "out of the box").

Behind the door on the side of the "welder" there is a niche where a bobbin is installed for a 5-kilogram coil with wire. There they also hide from prying eyes the change of polarities for working with flux wire. In action, Kaiser MIG/MAG-265 has proven itself exclusively in a positive way. However, it will be very difficult for beginners at first to find a common language with the device due to the lack of useful options for hot start and arc force. And the device weighs almost 13.5 kg, which slightly limits its mobility. These shortcomings are offset by a more affordable cost of the model than most peers.

| Rozetka.ua | 9 599 ₴ | To Store |

| Rozetka.ua | 9 799 ₴ | To Store |

| Rozetka.ua | 11 132 ₴ | To Store |

| Rozetka.ua | 11 352 ₴ | To Store |

| Rozetka.ua | 8 492 ₴ | To Store |

The guest from the Celestial Empire Edon MIG-280 is ranked among the kind of inverter-type welding machines engaged in welding metal parts and workpieces both in manual (MMA) and semi-automatic (MIG) mode.

The device "cooks" with a direct current from 20 to 280 A, using either melting electrodes with a diameter of 1.6-5 mm, or an electrode wire up to 1 mm in an environment of protective gases and without it. Switching between welding modes is performed by simply installing a two-position lever on the front panel of the device in the desired position. Also on it you can see the rotary knobs for changing the wire feed speed and smooth adjustment of the welding current.

The Edon MIG-280 is equipped with a number of helper functions in obtaining a high-quality result: Hot Start, Arc Force and Anti-Stick protection. Together with the "straight hands" of the installation operator, they are all aimed at creating a truly first-class weld without sparks and electrode sticking.

The additional assets of the device have a euro connector for connecting the sleeve (not included in the delivery package) and internal clips for changing the polarity in case you want to use a flux-welded wire. They regretted equipping the model except with a screen. However, an experienced welder will easily determine the required amperage to solve a particular problem "by eye". Well, a beginner will have to rely on the welding current adjustment scale framed by the corresponding handle when looking at the device full-face.

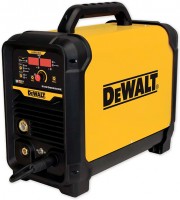

Intertool company is one of the most famous players in the arena of Ukrainian power tools. Under the brand's wing, all kinds of "tools" for construction and repair, as well as welding machines are produced. A bright representative from the "welders" squad is the combined model DT-4235.

The unit is used for welding with electrodes in manual mode and semi-automatic welding with wire. The cross-section of the electrodes in wire form can vary from 0.6 to 1.2 mm, which allows you to perform both delicate work and to lay a completely standard welding seam. The switch of welding modes "MMA/MIG" is placed on the front panel of the device housing.

In the Intertool case, the DT-4325 operates with welding currents from 30 to 250 A. The frequency of switching on the unit when working "to the fullest" is 60%. This means that for every 6 minutes of continuous welding, the device is allowed 4 minutes. rest. Separate rotary knobs on the control panel of the device are responsible for adjusting the arc afterburner and voltage in MIG mode.

To enhance the pleasant impression of the model, "buns" are designed in the manner of a digital screen for displaying the value of the welding current and an extended delivery package of the device. In addition to standard cables for electrode welding, wire welding cable, mask and hammer-brush, the device is equipped with a gas hose and a reducer. It lacks only the functions of hot start and anti-sticking of the electrode, which could be useful for beginners in welding.

The power tool under the sign of the east european brand Dnipro-M offers such a developed level of functionality that the nearest foreign analogues in the same price category did not even dream of. One of the significant items of income of the trademark is formed by welding machines, in particular, an advanced model of a semi-automatic inverter SAB-310.

The unit will appeal to both welding professionals and beginners in this path. Judge for yourself, he "cooks" both in manual MMA mode using melting electrodes with a diameter of 1.6 to 5 mm, and in the role of a semi-automatic, using a wire with a cross section of 0.8 to 1 mm. The welding wire is fed automatically at a speed of up to 9.1 m/min. The range of welding current in MIG mode is smoothly adjustable from 20 to 250 A, voltage — from 13 to 22.5 V. All indicators can be monitored visually, relying on data from two digital displays on the front panel of the device.

The front part of the welding machine body is generously dotted with a whole scattering of controls for selecting the most optimal conditions for a specific task. For example, the three-position key "2T-SPOT-4T" allows you to switch between wire working modes (short, long seam and spot welding) in the blink of an eye. The time of spot exposure in the SPOT mode is set by a separate mechanical "twister" in the range from 1 to 9 seconds.

The device remains operational when the voltage in the power supply network subsides to 160 V. The regulars of garage cooperatives with breathable wiring will be especially pleased with this function. The fact that the device is equipped with a removable 3-metre-long European sleeve and an improved cooling system that allows the device to stay "afloat" longer when working without interruption at maximum loads deserves special respect. Finally, the unit is sharpened into a compact (330x430x630 mm) and lightweight body (8.6 kg) — according to the combination of these parameters, the model is one of the most compact in the class.

The experimental plant of welding equipment of the E.O. Paton NPP produces a wide range of products for both industry and east european use. In the consumer segment, one of the leading positions is rightfully occupied by the Standart series of semi-automatic inverters. The PSI-250S model is the most performant in it.

The device plays the role of a "universal soldier" very well. Judge for yourself, in addition to the semi-automatic MIG/MAG mode, the device can be entrusted with manual welding with electrodes up to 6 mm in diameter and argon-arc welding of TIG non-ferrous metals. The Hot Start function provides an easy start of the process (increases the welding current at the start). Also, the options of smooth adjustment of the arc afterburner and anti-sticking of the electrode are put on guard of the quality of the weld.

The welding machine greets the user with a push-button control panel with a digital display in the upper left corner. The screen shows the selected amperage in the range from 12 to 250 A. The welding voltage (12-28 V) and the wire feed rate (3-16 m/min) can also be adjusted. The cherry on the cake is a "smart" fan that increases the force of rotation of the blades when the parts are heated in order to avoid overheating of the device.

The model slightly let down only one item of the programme. It is associated with the frequency of switching on at maximum currents (45%).In non-stop mode, the unit is able to work tirelessly when the welding current is lowered to 134 A. For home purposes and semi-industrial use, the device's capabilities are more than enough.

We understand what a smart home is, why it is needed and on the basis of which solutions to create it.

Omnivorous pumps for pumping out cesspools, draining sewage and removing meltwater.

One SSD is good, two are better, and a RAID array is just flying away.

These centrifugal juicers squeeze out juices from fruits and vegetables of any hardness.

TOP laptop mice with a wire that will never get old.