Inverter drive in household appliances: pros and cons

We independently test the products and technologies that we recommend.

1. Operating principle of inverter motor

Inverter systems allow you to keep the heart of your home appliance constantly “beating” and smoothly adjust the power, selecting it for specific needs. At a minimum, this reduces premature wear of components. To save energy, inverter motors do not turn off completely - they reduce the speed when there is no need to work “at full speed”. Smooth transitions from high to low speeds are less harmful to the home appliance than constant switching on/off.

The inverter technology is based on the principle of double voltage conversion. First, the sinusoidal voltage at the input is converted into direct voltage, filtered and smoothed. At the second stage, positive and negative control pulses are formed from it. With their help, an alternating voltage of the required magnitude and frequency is created at the converter output, which is then fed to the engine. The operating principle of the engine itself does not depend on the presence of an inverter, but this additional unit makes it possible to control the operation of the electric motor within wide limits.

Inverters are often included in circuits with asynchronous motors. They solve problems with high starting currents and overloads, and also allow changing the rotation speed of the electric motor rotor from tens of rotation per minute to several thousand. The most important advantage of such a combination is the absence of a vulnerable brush assembly in the motor design, which is the hallmark of collector-type electric motors. Over time, the current-carrying brushes in them wear out and need to be replaced. The main characters of motors with an inverter drive: a rotating rotor with permanent magnets and a stationary stator with inductance coils. However, control circuits, called inverters, can be implemented in completely different ways in different devices.

We will not delve deep into the technical side of the issue. It is better to focus on the advantages and disadvantages of inverter technology, as well as the features of its applicability in specific groups of household appliances.

2. Refrigerators and freezers

Refrigerators and freezers with a traditional linear compressor are systematically switched off when the optimum temperature in the chamber is reached. The accuracy of its maintenance varies within 3-5 °C (depending on the specific model). With each subsequent switch-on, the refrigerator motor experiences increased starting loads, its elements heat up, which provokes premature failure of the units, and household members clearly hear a hum during the compressor operation.

The inverter compressor starts at low speeds, gradually building up its power. First, it cools the air in the chamber to the desired temperature, then slows down to maintain it. The engine sometimes works almost silently at minimum speeds, then slightly increases its power and its measured "rumbling" can be heard. This mode is most favorable for the compressor, since it works without starting overloads and, due to their absence, consumes less electricity.

Advantages of inverter compressors in refrigerators and freezers:

- high-precision maintenance of the set temperature in the refrigeration and freezing chambers;

- low noise;

- no interruptions in operation or shaking of the body when the compressor is turned on;

- economical energy consumption (energy efficiency class A++ and higher);

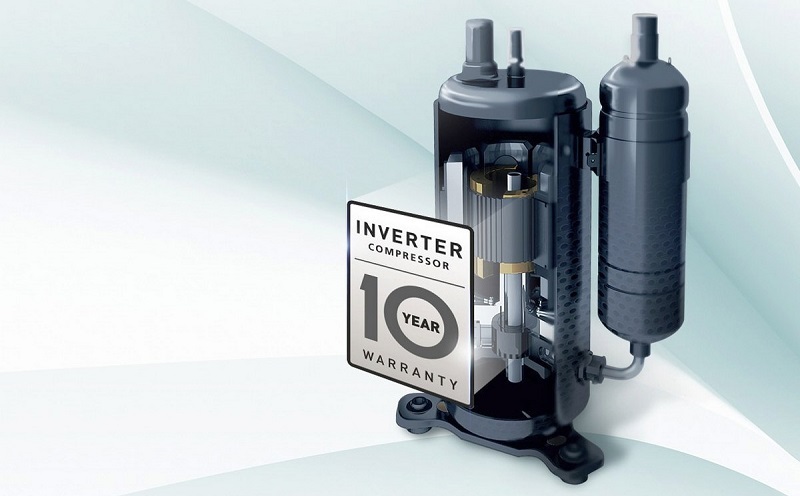

- long service life (10 years of warranty on an inverter drive directly from the manufacturer is quite normal practice today).

Disadvantages of inverter drive:

- sensitivity to voltage fluctuations in the power supply network (it is advisable to get a voltage stabilizer);

- high cost of equipment and high cost of repairing the refrigerator when it breaks down.

3. Washing machines and dryers

In previous generations of washing machines, torque is transmitted from the electric motor to the drum using a belt drive. The drive belt has a limited service life and, together with the current-carrying brushes, causes increased noise, which also depends on the motor speed. Machines with inverter control are free of such disadvantages. In addition , they are increasingly being produced in a direct drive configuration - in models of this kind, the drum is located directly on the motor shaft.

Washing machines with an inverter motor spend less energy on drum rotation, frequency regulation allows sensitive control of the number of its rotation, plus "washing machines" of this kind can boast of quiet spinning and precision of washing mode settings. In drying machines, the inverter is used more for the sake of saving electricity consumption and achieving low noise during operation.

Moreover, they are many times more reliable than their peers with belt drive.

Advantages of inverter-controlled washers and dryers:

- improved washing quality thanks to flexible speed control;

- optimal balancing due to the placement of the drum and rotor on the same shaft;

- precision of washing mode settings;

- low noise level of the operating motor;

- high efficiency due to the absence of friction losses;

- long service life;

- economical energy consumption;

- no need to service engine technical components.

Disadvantages of inverter drive:

- relatively high cost of finished products;

- complexity and high cost of repairs.

4. Dishwashers

Washing dishes is often postponed until nighttime. This is where the advantages of inverter-controlled dishwashers come into play:

- low noise level (around 40 dB);

- non-wasteful consumption of electricity (allows you to save on electricity bills when using multi-zone electricity meters);

- more effectively implement assigned programs.

The advantages of inverter control in dishwashers include:

- automatic determination of energy consumption depending on the load;

- low noise threshold;

- "fuel" efficiency (low energy consumption);

- significant increase in the service life of equipment.

The disadvantages of the inverter drive “under the hood” in dishwashers are quite standard:

- higher price tag compared to “classmates”;

- expensive engine repairs in case of breakdowns;

- increased sensitivity to voltage surges.

5. Air conditioners

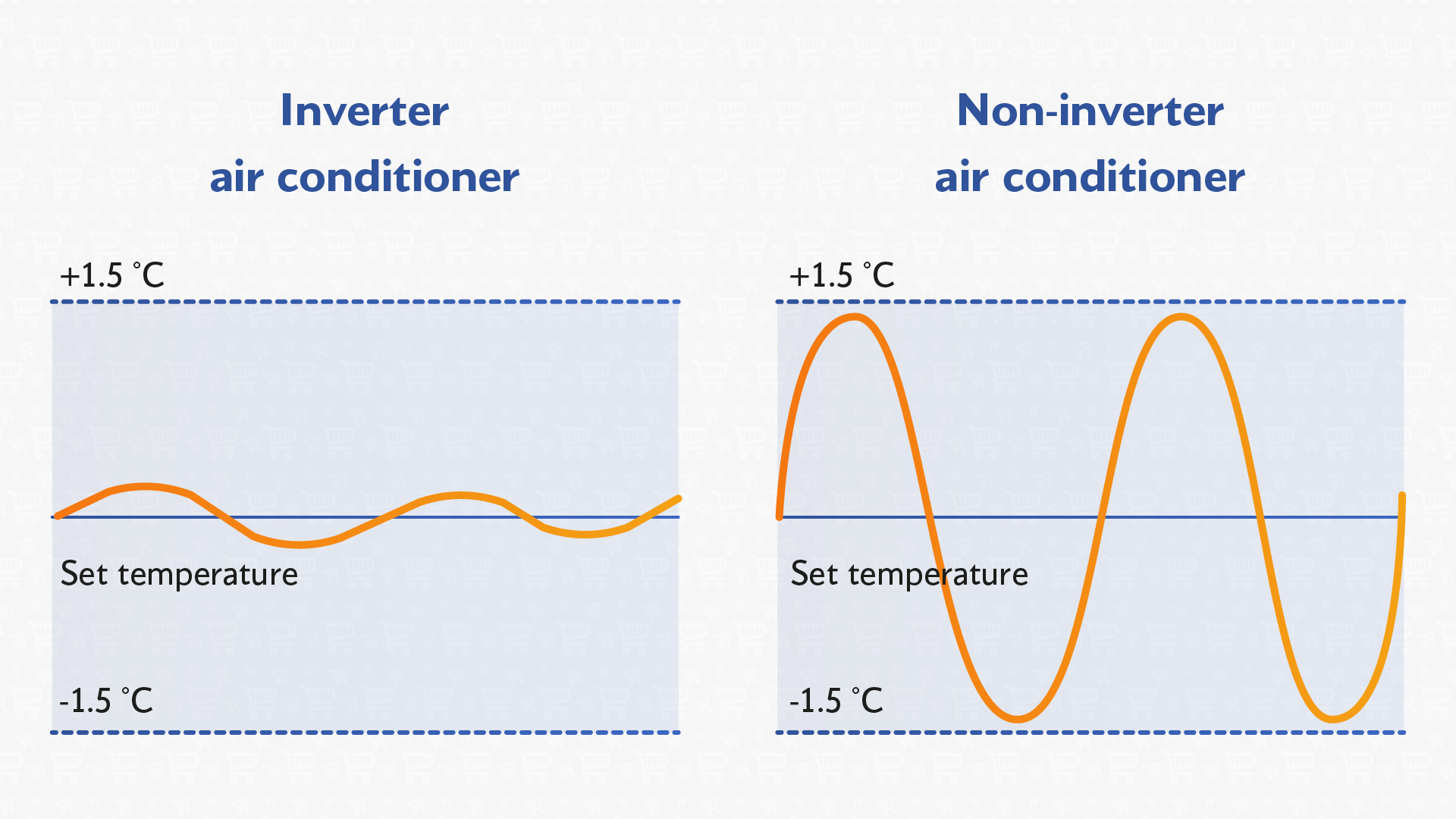

In inverter air conditioners, the compressor remains on permanently, and its power changes smoothly depending on the temperature. Such climate control equipment consumes less electricity and accurately maintains the set temperature. The inverter converter sets the compressor speed in such a way that the set temperature is maintained. And the compressor, due to its continuous operation, does not freeze in winter.

Advantages of inverter controlled air conditioners:

- high-precision maintenance of a given temperature regime;

- work at low minus temperatures of outside air;

- low noise;

- low power consumption;

- durability.

Disadvantages of inverter drive:

- high cost of climate control equipment and its repair;

- sensitivity to power supply quality.

6. Microwave ovens

A mandatory attribute of a microwave oven is a magnetron. Often it has one fixed power, and the required final radiation power is achieved by periodically turning the magnetron on and off. In microwaves with inverter control, the emitter works constantly, and its power changes smoothly depending on the selected mode. This ensures uniform heating of food and, as a result, maximum preservation of its taste qualities.

Advantages of inverter control of microwave ovens:

- spacious internal chamber due to the absence of a bulky transformer;

- preserving the beneficial properties of products and improving the taste of reheated dishes;

- saving time on heating food;

- high energy efficiency;

- silent operation;

- long service life.

Disadvantages of the technology:

- high cost of final products;

- limited range of models with inverter drive.

Articles, reviews, useful tips

All materials