Bicycle tyres marking

The condition of the bike tyres must be carefully monitored. Worn-out tyres worsen the bike ride quality, lead to problems with braking and handling, and simply make it unsafe to ride. The fundamental factor when choosing tyres for a bike is the appropriate size, selected in accordance with the size of the bicycle wheels:

- wheels from 12" to 20" are standard for children's and BMX bikes, folding models of city bikes;

- 22" or 24" wheel sizes are found predominantly in teen bikes ;

- wheels 26" and 27.5" – are the prerogative of mountain bikes and fatbikes ;

- the 28" diameter is found in city bikes and road bikes ;

- large 29" wheels are installed on MTB bikes.

Note that wheel size is usually indicated in inches. However, for marking the size of bicycle tyres, this measurement value is not the best way, since the inch tyre marking system reflects only approximate indicators – it is not accurate enough. Ideally, you should focus on the size of the bike tyres in millimeters.

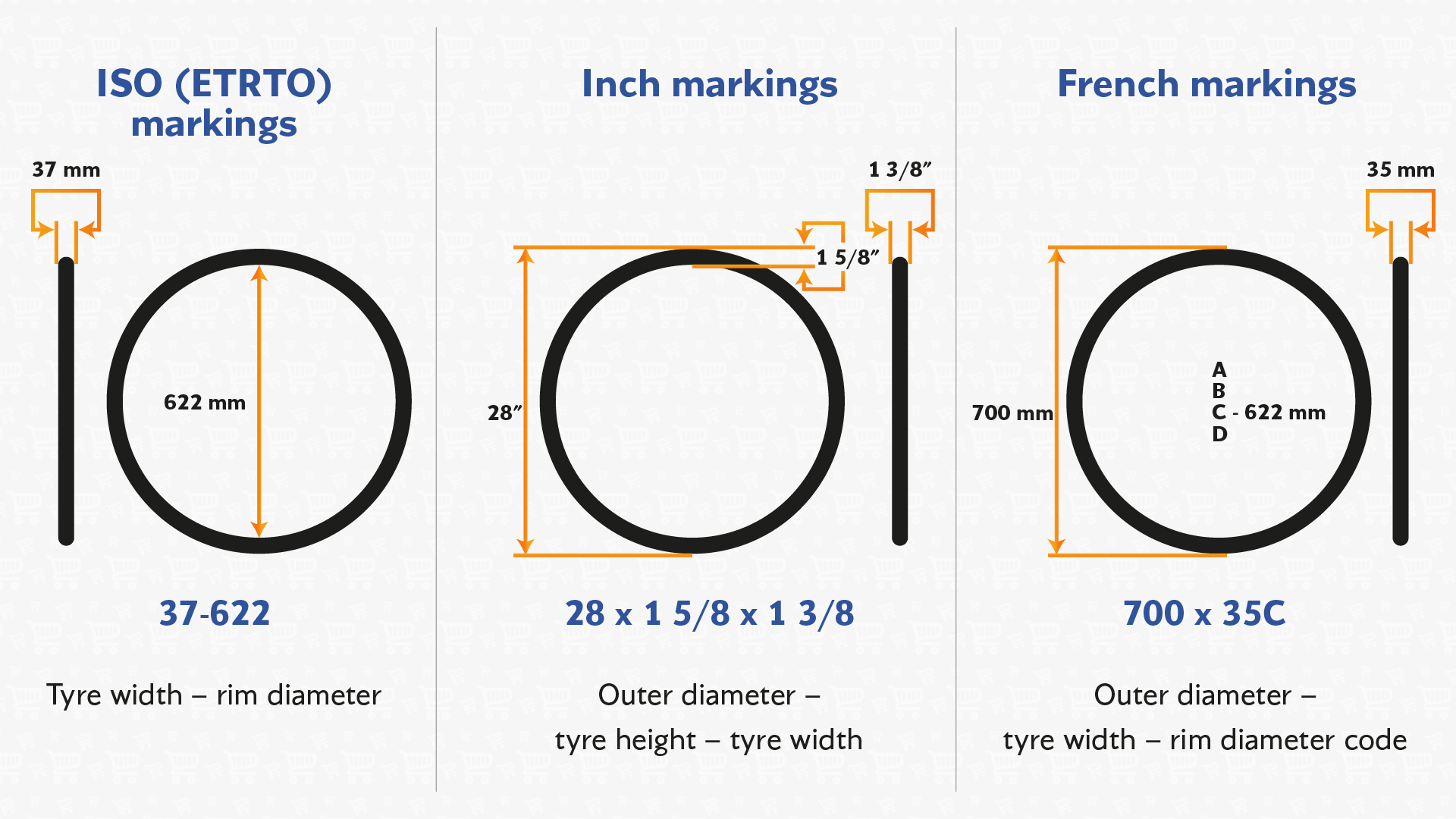

Size in millimeters

The most accurate size of bicycle tyres is reflected in the European marking system according to the ETRTO (European Tyre and Rim Technical Organization) specifications. Tyre size is written as:

37-622

- 37 – tyre width in millimeters;

- 622 – inner diameter in millimeters, which determines the possibility of installing a tyre on a wheel rim.

Size in inches

In the inch marking system, combinations of two or three digits can be used. First option:

24 x 1.75

- 24 – outer tyre diameter in inches;

- 1.75 – approximate tyre width in inches.

The second option is written as follows:

28 x 1 5/8 x 1 3/8

- 28 – outer tyre diameter in inches;

- 1 5/8 – approximate bike tyre height in inches;

- 1 3/8 – approximate tyre width in inches.

The inch system defines approximate sizes, which makes it difficult to match bike tyres with the same marker for different types of bikes. In particular, diameters of 559 mm, 571 mm and 590 mm are marked as 26 inches, and tyres with a diameter of 622 mm and 635 mm are equated to an inch size of 28 inches. Bicycle tyres 28 and 29 inches do have the same rim diameter of 622 mm – they differ only in height and thickness.

|

| Basic sizes in different bicycle tyre marking systems. |

To avoid misunderstandings, select new bike tyres taking into account the size of the old ones. And it is best to choose tyres, in which the designations in inches are duplicated by European markings in millimeters according to ETRTO standards.

French marking system

French marking implies an alphanumeric designation of the size of bicycle tyres. It is written in this format:

700x35C

- 700 – outer tyre diameter in millimeters;

- 35 – tyre width in millimeters;

- C – inner diameter. The C letter corresponds to an inner size of 622 mm. In general, tyres in the French system can be labeled with letters from A to D (from smallest to largest).

The French marking system is used on tyres for road, gravel, hybrid and city bikes, but tyres for the mountain bikes are not marked with it.

Carcass density and tread stiffness

The carcass that gives the bike tyre its shape is woven from various synthetic threads (for example, nylon – marked with the inscription Nylon). The density of their weaving is indicated by a two- or three-digit number labeled TPI or EPI. The abbreviation TPI (Thread Per Inch) is generally accepted throughout the world, while EPI (Ends Per Inch) is a European-style carcass density marking. There are no fundamental differences between these characteristics.

|

| The TPI (EPI) measures the density of a bike tyre carcass. |

The higher the TPI (EPI), the denser the cords lie in the tyre carcass. Therefore, high-density tyres have good strength due to less rubber in the sidewalls, better puncture resistance, higher pressure resistance, and are also very light. Conversely, models with a low TPI have fewer cords and more rubber – such tyres weigh more, but are cheaper.

The strength of bicycle tyres is also described by the structure of the sidewalls:

1. LiteSkin – tyres with lightweight and thin sidewalls (for fast driving on smooth, hard roads). 2. SnakeSkin – tyres with protected sidewalls to prevent their cuts (sharpened for conquering off-road, better resist punctures).

The tread stiffness of bicycle tyres is marked with the following designations:

- 40-45a – soft tread;

- 50-60a – medium soft tread;

- 60-70a – hard tread.

A stiffer tread provides good rolling and reduces the chance of tyre damage, but reduces traction and riding comfort. Note that the softest bicycle tyres are often labeled with the abbreviation ST (Super Tacky).

The degree of stiffness of the rubber compound of bicycle tyres can also be determined by colour coding. They are often presented in the form of a coloured strip running along the entire tyre along the tread:

- Purple stripe – ultra-soft rubber compound.

- Orange stripe – soft rubber.

- Blue stripe – medium hard compound.

- Red stripe – hard rubber for good rolling.

|

| By the colour of the stripes on the tread, you can visually determine the degree of stiffness of the bicycle tyre. |

Soft compounds give sensitive steering responses and provide good grip, however, the softer the rubber compound, the faster the tread wears out. Bicycle tyre models with two types of compound in the design can be designated as Dual Compound, with three – by 3C index or the phrase Triple Compound.

As for the beading cable, the steel materials of its manufacture are marked with the indices Steel, Unfold, etc., Kevlar – Kevlar, Folding, Foldable, etc.

Sometimes the maximum load capacity is indicated on the tyres:

MAX. LOAD 125 kg (275 LBS)

The load limit value is indicated at the maximum allowable tyre pressure. It is measured in kilograms ( kg) or pounds ( LBS).

Bicycle tyre pressure

In bicycle tyres, it is necessary to maintain the required pressure on a constant basis. After all, it is the tyres that hold the tube pressure and transmit vibrations to the bicycle frame. Recommended tyre pressure is indicated as:

Inflate to MIN. 36 PSI / 250 kPa – MAX. 60 PSI / 420 kPa

The pressure must be within the specified range. In this case, the following measurements are used:

- PSI (Pound-force per Square Inch) – pounds per square inch (Europe and the USA);

- kPa – kiloPascals (or simply Pascals Pa);

- BAR – pressure in bars (or atmospheres, 1 bar = 1 atm); to find out the pressure in bar, it is necessary to divide the indicated value in kiloPascals by 100.

Bicycle pumps with a pressure gauge are usually marked with a universal scale that allows user to navigate different pressure measurements.

It is not recommended to inflate the wheels to the maximum pressure in order to avoid bursting the tyre in hot weather on hot asphalt. In some cases, after specifying the operating pressure range, the prefix Cold may be written. If it is present, it means that you need to check the pressure in “cold” (unheated) tyre.

|

| Tyre pressure is supposed to be monitored using a bicycle pump with a built-in pressure gauge. |

In a number of models of bicycle tyres, all sorts of design tricks are used to protect tyres from punctures. For this, anti-puncture belts are made of elastic rubber or Kevlar. Such layers protect the tyre from punctures in the tread area, however, such protection makes the tyre heavier and impairs rolling. Bicycle tyres with puncture protection are labeled differently: Protection, Puncture protection, Puncture resistance, Flatless, Anti-flat, Guard, Safety, etc. There is no single generally accepted designations in this matter.

Tubeless bicycle tyres TL (TubeLess) have good maintainability. Punctures in them can be quickly eliminated by using special viscous sealants. In case of emergency, a punctured tubeless wheel is repaired on the road with the help of a spare tube.

Mounting axle and direction

The vast majority of tyres for bicycles are available in a universal version. At the same time, there are tyre models designed for installation on the front axle. In the manufacture of such tyres, a compound with a low level of stiffness is used, which ensures more sensitive reactions to steering. Tyres on the front axle are labeled in the manner of Front Only. On the rear axle of the bike, such tyre wears out faster.

Bicycle tyres with a unidirectional asymmetric tread pattern are supposed to be installed, guided by the designations of the wheel rotation direction: Rotation →, Drive →, Rotation Direction →. The direction of rotation is indicated by an arrow. Moreover, for the front and rear wheels, it can be radically different ( ←Front, Rear→).

Date of manufacture

The date of manufacture of a bicycle tyre is written in four digits (often inside an oval). The first two digits of the numeric code contain information about the week of production, the last two digits are the year of manufacture.

|

| A tyre with a manufacturing date of "1220" was released during the 12th week of 2020. |

Behind the 3522 marking of the date of manufacture is the 35th week of 2022. When choosing new tyres for a bike, you should give preference to newer models that were released no more than a year ago. Stale tyres dry out and become covered with a web of microcracks, which impairs their ride quality and reduces travel safety.

Additional designations

In addition to standard markings, other inscriptions are also applied to the sidewall of bicycle tyres. For example, additional information about the manufacturer, website address, the possibility of using tyre in the cold season, and so on. There are no standard rules for additional designations of tyre products for bicycles. But some common features are still found.

So, according to the purpose, tyres are as follows:

- City, Urban – tyres for city bikes;

- Touring, Tour – tyres for touring bikes;

- Road, Race – road tyres;

- MTB, Trail, Downhill, Freeride, Cross, All-Terrain – tyres for mountain bikes and their specialized varieties;

- BMX – tyres for BMX bikes ;

- Gravel – gravel tyres;

- Cyclocross – tyres for cyclocross;

- Electric, E-Bike – tyres for electric bicycles.

The seasonality of bicycle tyres is indicated by the following symbols:

- W, Winter, Snow, snowflake icon – winter tyres.

- All-Seasons – all-season bike tyres.

|

| Bicycle tyres with reflective stripe provide better visibility of the rider on the road in the dark |

Bicycle tyres with reflective stripes are labeled Reflect, Reflex or Reflection. At night, such stripes make the cyclist more visible on the road.

Knowing the basic principles of labeling bicycle tyres will help you decide on the right tyre model and not waste your money. You can also save the old tyres for an example and take it with you to buy a new one.