How a magnesium anode helps a water heater last longer and how it should be maintained?

Before making a choice in favor of a particular model of storage water heater, we recommend you to familiarize yourself with the benefits of the internal magnesium anode, which continuously protects the walls of the internal water tank from corrosion.

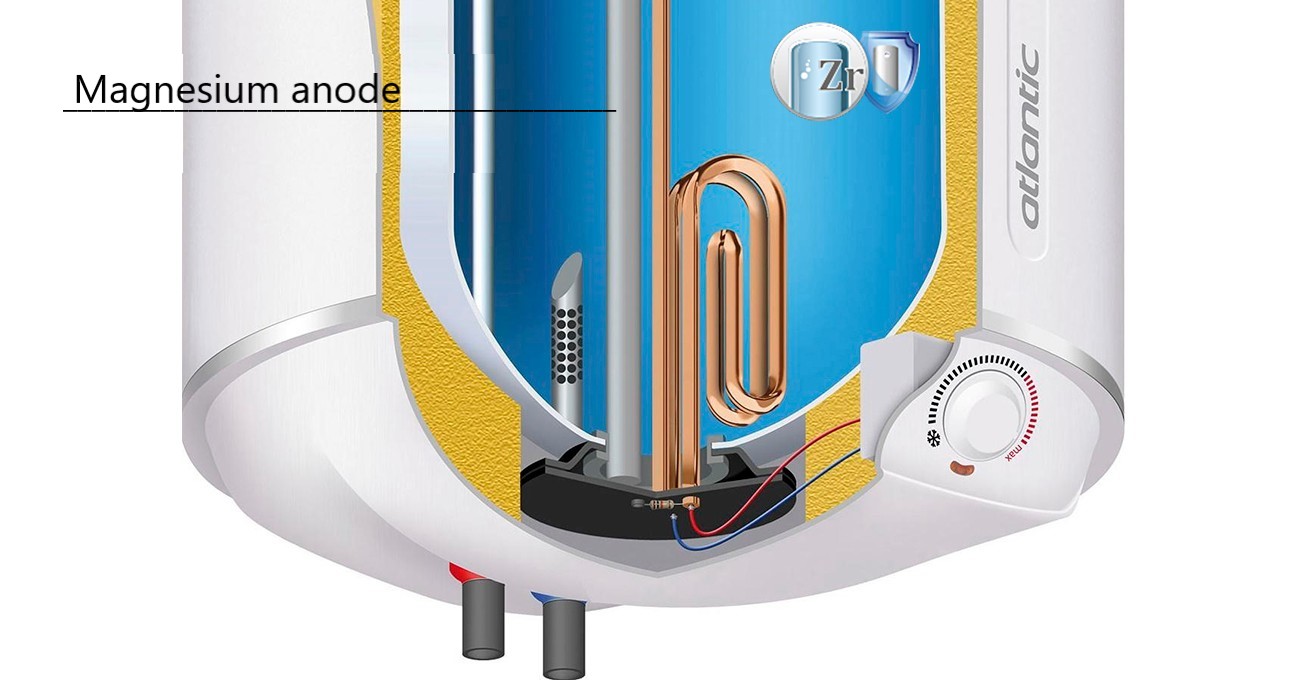

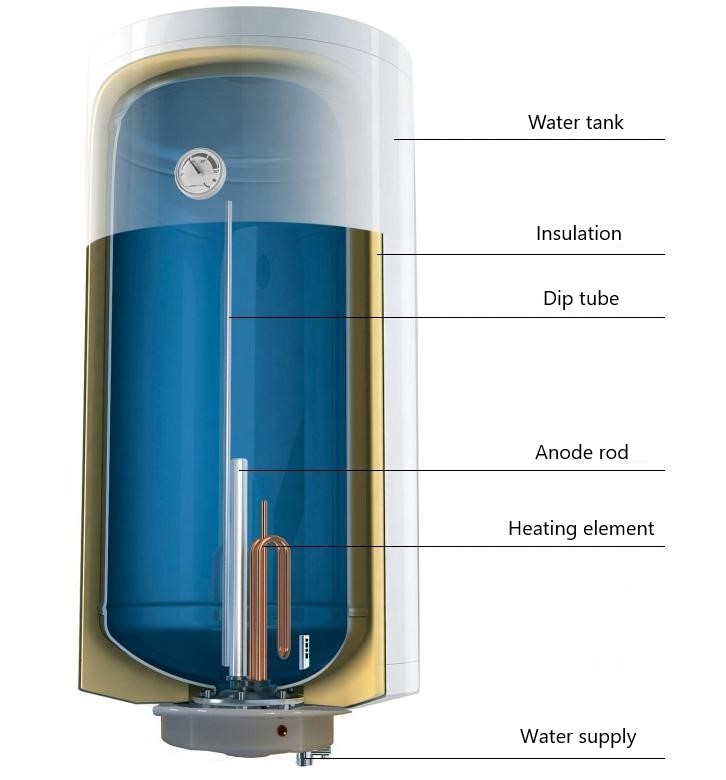

Design of the internal tank of a storage water heater

The design of the storage tank, where the water is heated, is definitely the place to start. This is the most important element of the water heater, on which its long life depends. Manufacturers offer internal tanks made of plastic, steel and copper. The operating pressure in the storage tank can reach 8 bar, which dictates the possibility of using one or another material. For small non-pressure devices with a 30 L tank, plastic can be used, and the tanks of pressure models for 50 – 100 L are made of metal. A copper tank is very good in a water heater because it is highly resistant to corrosion and bacteria. But the limited number of models and the exceptional high cost of such devices forces us to look for a real alternative among products with a steel tank.

|

These tanks are made of either stainless food-grade steel or carbon steel with a subsequent inner coating of enamel or glass-ceramic. For the quality and durability of the tank, strength, thermal resistance and a uniform structure of the internal surface are required, as well as reliable connection of the protective coating layer with the crystalline structure of the base metal. After all, if a crack forms on its surface, the tank can no longer be repaired. And for stainless steel tanks, the most important criterion is the quality of the weld, which largely determines the longevity of the device. For better temperature maintenance of the heated water, the tank is insulated from the housing with a special material with low thermal conductivity.

When comparing stainless steel storage tanks and coated tanks, you can’t help but wonder, which one is better and more durable? It’s difficult to give a definite answer, because a lot depends on the specific manufacturer and the quality of the materials. For example, Chinese-made stainless steel cannot stand any comparison in quality with Swedish steel. Comparing the prices of devices with stainless steel and enamel tanks will not be correct, because the former are traditionally more expensive. Manufacturers of water heaters with both types of tanks on the HTW market offer approximately the same warranty of 7 – 8 years, and for some models – up to 10 years. But in order for the water heater to serve the given period of time, the inner surface of the water tank needs proper protection and maintenance.

Everything you need to know about the magnesium anode: purpose, operating principle, maintenance

For many people unfamiliar with electrochemical processes, the term "magnesium anode" may seem as obscure as Chinese characters. However, this small rod located inside the tank serves as the primary protector against rapid corrosion and potential damage to the tank itself. Remarkably, the lifespan of the entire unit depends on this small, seemingly insignificant metal rod.

What is a magnesium anode for?

The magnesium anode of the water heater is the only effective means of passively protecting the inner surface of the tank and heating element from electrochemical corrosion. But if a broken heating element is not difficult to replace, then a leaky tank cannot be repaired and the water heater will have to be thrown away. It should be noted that anodic corrosion protection does not help with scale formation, which is more affected by the quality of tap water. However, the rate of oxidation of hard water salts by the anode is limited, so the additional use of filters is recommended for the protection to function effectively.

|

We all know what rust is, but we rarely think about where it comes from. Any steel product is sooner or later exposed to corrosion, and the material of the internal tank is no exception. When water is heated, oxygen is released, which actively interacts with the metal of the tank and heater, forming rust on their surface. The rust deposits cause the walls of the storage tank to thin and can destroy the heating element. To prevent this, a special magnesium alloy rod is installed inside the water heater tank, which is more active than iron. It becomes a distraction and the oxygen switches to destructive action towards the anode. This distraction prevents corrosion of the water heater's metal surfaces by destroying the magnesium anode, which gradually deteriorates as it oxidizes, reducing its protective properties. The anode also reduces the negative effects of hard water and stray currents on the internal components of the heater.

The most susceptible to corrosion are welds that have a heterogeneous crystalline structure, which is more threatened by destruction than the base metal. The welding point of the steel tank is always a weak point of the steel structure, which needs special protection — because the tank begins to rust just from the welded seam, resulting in leaks from the inner tank. It should be borne in mind that inexpensive food grade stainless steel, which is used as a material for storage, does not have the proper durability. Unfortunately, high-quality stainless steel with good anti-corrosion properties is very expensive and tanks made from it would make water heaters inaccessible to the mass consumer.

It may seem that only stainless steel tanks need protection, but it is not true. Despite the fact that the composition of the enamel in coated tanks is selected in accordance with the expansion coefficient of steel, repeated heating and cooling cycles still lead to cracks and chips of the protective surface, allowing water access to the exposed metal. Therefore, tanks with glass ceramics and enamel coating can also have protective anode rods in their design.

Change the anode on time

Anode protection in the form of a magnesium rod is a consumable material that is destroyed during operation of the water heater. As the rod oxidizes, the active area of ion exchange decreases, reaching a critical value over time. After this, oxygen is taken up by the remaining accessible metal surfaces of the water heater, so the remains of the anode rod corroded by corrosion require timely replacement.

The lifespan of the anode varies from model to model and depends on the length of the rod, but in most cases it should be replaced when it has worn out by 60% to 70%, when it is no longer effective. The degree of wear in this case is determined visually during routine maintenance of the water heater. If the lack of practice does not allow you to determine the degree of wear of the anode, it is better to replace it, especially since it is very easy to do so. If we talk about the time interval of anode replacement, the recommended periodicity is 1 – 2 years. But it is better to do it annually. It is allowed to use a larger rod for replacement, which will last longer than the standard one. Keep in mind that untimely replacement of the anode can lead to a leakage of the tank after six months of active use.

Regular water heater maintenance includes not only replacing the protective rod, but also descaling both the heating element and the interior walls of the tank. This approach is sensible, as replacing the anode opens up access to the insides of the appliance and it would be imprudent not to take this opportunity. An additional advantage of independent water heater maintenance is the experience gained and the ability to assess the level of contamination and rate of magnesium rod wear over the previous period of use. Such data will help to determine the required frequency of future maintenance work.

How to change the anode yourself

Magnesium rods have different diameters, lengths and thread sizes. As a rule, each water heater model is designed for its own anode sizes, but there are also standard designs suitable for many models. Typically, the anode is installed using a threaded rod into the flange of the water heater next to the heating element.

|

Now let’s look at the algorithm for replacing a magnesium rod using the example of a wall-mounted water heater with the anode and heating element located on a common area of the bottom flange of the tank:

- First of all, the appliance must be powered off and then you should wait for the water to cool down;

- Having turned off the water supply, open the drain valve and empty the tank with the hose;

|

- Next, unscrew the fastening and remove the bottom lid, under which the thermostat is located: our task is to remove it, having previously disconnected the contacts;

- Using a wrench, unscrew all the bolts securing the flange in which the heating element and anode are installed;

- Carefully remove the flange unit, placing a basin at the opening to drain the remaining water. As a rule, the unit is removed with force due to the sticking of the rubber ring seal;

|

- To remove the old anode, you can use pliers. The new rod should be screwed into the threads by hand, without tightening it too much;

- Descale the heating element by gently scraping it off with a knife and then scraping it off with sandpaper. Descaling the heating element improves its thermal conductivity and makes energy consumption more economical;

|

- Don't forget to clean the inside walls of the tank. To do this, you can use regular dishwashing cleaning products. After this, you need to thoroughly rinse the tank under running water;

- Reassembling the water heater is performed in the reverse order. Before checking the operation of the unit, do not forget to fill the tank with water, after which you can plug in the device. Without turning on the heat, open the water supply until a stream flows from the hot water tap. At this stage, you need to eliminate possible leaks by checking all connections. If everything is in order with this, then the water heater can be used.

|

What about water heaters that do not have an anode installed by design? You can make modifications to such models yourself by attaching a magnesium protection rod to the temperature sensor tube with copper wire. In exactly the same way, you can solve the problem when it is impossible to remove the rod of a destroyed anode.

General recommendations for protecting the water heater to extend its service life

- The timeless and fundamental advice is to attentively observe the operation of the water heater. Any new noises such as hissing or humming emanating from the tank can provide valuable insight into underlying issues, akin to how unfamiliar engine sounds aid mechanics in making accurate diagnoses. While various factors can contribute to noise in a water heater, it invariably signals the necessity for preventive maintenance. For instance, the distinct hissing noise occurring in the tank when the hot water tap is turned on signifies scale buildup on the heating element, indicating that it's time to replace the protective rod;

- When purchasing a new water heater, choose a model equipped with anode protection for the tank. If you have a model without a protective rod, then simply follow the manufacturer’s recommendations, or make an “upgrade” by installing the anode yourself;

- If there is a magnesium anode in the design, never allow the water heater to operate without it, changing it regularly after the prescribed period of time;

- Remember to buy and install filters if you use hard tap water of low quality. This will significantly reduce the salt concentration and protect the appliance from scale formation, as well as allowing the magnesium anode to operate more efficiently.

It should be noted that the means of protection used are sometimes useless and unjustified. Here, it is necessary to take into account the composition of the water and the operating mode of the heater. For example, if you do not heat water above 55 °C, there is little or no scale build-up in the water heater, but there is an increased risk of Legionella bacteria, the prevention of which requires special protection. And with low mineralization of water with a low salt content, using an appropriate filter will be a waste of money. When hard water is used for supply, it is better to buy a device equipped with a dry heating element, which is not afraid of scale.

Articles, reviews, useful tips

All materials