Generators: answers to frequently asked questions

We independently test the products and technologies that we recommend.

1. What power does a generator need for a private home?

The generator power is selected depending on the expected number of connected electrical appliances. In this case, their total energy consumption must be taken into account. Data about this can be taken from the technical documentation for specific equipment, and the average parameters of power consumption by different household appliances and power tools are given in the table:

| Power tools | Appliances | ||

|---|---|---|---|

| Consumer | Power, W | Consumer | Power, W |

| Jigsaw | 250-700 | Electric lamps | 5-50 |

| Electric sharpener | 300-1100 | TV | 100-400 |

| Drill | 400-800 | Fridge | 150-600 |

| Electric planer | 400-1000 | Computer | 400-750 |

| Hammer | 600-1400 | Vacuum cleaner | 1000-2000 |

| Grinder | 650-2200 | Hair dryer | 450-2000 |

| Circular Saw | 750-1600 | Iron | 1000-2000 |

| High pressure pump | 2000-2900 | Toaster | 500-1000 |

| Electrical appliances | Coffee maker | 800-1500 | |

| Consumer | Power, W | Oven | 2000-3500 |

| Water pump | 500-900 | Electric kettle | 2000 |

| Electric motors | 550-3000 | Heater | 1000-2000 |

| Fan heater | 750-1700 | Electric stove | 1100-6000 |

| Compressor | 750-2800 | Boiler | 1500-2000 |

| Air conditioner | 1000-3000 | Microwave | 700-1000 |

| A circular saw | 18000-2100 | Washing machine | 1000-2500 |

To the resulting amount of power consumption, it is necessary to add about 20% in reserve - this will protect the generator from working with overload, ensure rational fuel consumption and create a buffer for connecting additional electrical appliances.

In general, for a small private house, a generator with a capacity of 3 - 4 kW of power will be sufficient. This takes into account the operation of lighting, refrigerator, TV and Internet, and periodic use of a microwave oven. If the generator is supposed to set up the operation of one or two electric stove burners, you will need a more powerful model ( 4 - 5 kW), or a pump for autonomous water supply from a well - even more powerful (at least 5 - 6 kW, and preferably 6 - 8 kW). The fact is that non-inverter climate control equipment and conventional well pumps consume on average 1 - 2 kW of power, but they require high starting currents (3 - 5 times more than in the nominal operating mode). The generator must cope with such reactive loads and withstand short-term power surges to ensure trouble-free operation.

2. Is it possible to make the generator turn on and off automatically?

You can switch the generator on and off without user intervention through an automatic transfer switch (ATS or ATS). Generators with an integrated ATS unit and models with a connector for connecting an ATS module are available for sale. Such a unit determines the presence or absence of voltage in the main network, and if the electricity is lost, the automation sends a signal to the generator to start. When the power supply is restored, the automation turns off the engine and turns off the generator.

All such generators are equipped with an electric starter and battery, so that the equipment starts without human intervention. However, the method of connecting a generator using an automation unit is the most complex and expensive to implement. It is justified if electricity goes out frequently.

3. How long can the generator operate continuously?

It is difficult to answer this question unambiguously. Guided by logic, we can assume that the generator is able to operate continuously as long as there is fuel in the fuel tank. But in practice, not everything is so simple - at a minimum, everything depends on the design of the generator set and its cooling system, as well as the type of fuel used.

In the most common segment of portable gasoline generators with classic air cooling, the continuous operation time reaches 5 - 8 hours, after which the equipment will need a rest (from 15 minutes to 1 hour). At 100 percent load, the time of continuous operation without a “smoke break” can be significantly reduced - up to half an hour (to avoid overheating).

Non-stop operation of diesel generators is possible for 10 hours or longer. So, some stationary models can easily work for more than a day. The specific duration of continuous operation is usually prescribed in the accompanying technical documentation for the generator.

Household models of gas generators with an air cooling system operate continuously for 5 – 8 hours. But stationary industrial gas generators with direct connection to the gas main and liquid cooling can be used continuously for over 100 hours - they are a priori designed for long-term non-stop operation.

4. What is the resource of the generator?

The engine life differs significantly depending on the design of the generator engine and, again, the type of fuel used. Simple and inexpensive gas generators have a service life of about 600 - 800 hours, middle-class models - over 1000 hours. Generators with branded engines(Hyundai, Honda, Yamaha, etc.) will last the longest - their service life often exceeds 3000 hours.

A built-in info display is usually used for these purposes.

Small generators with a diesel power plant last over 5,000 operating hours; mid-range models easily cover a mileage of 10,000 to 20,000 operating hours. Stationary diesel power plants can operate productively from 40,000 engine hours.

Gas generators will last the longest - 10,000 hours or more. Such a long service life is due to the fact that gas during combustion emits a minimal amount of solid particles that wear out the pistons and cylinders of the power unit. However, mixed fuel models ( gas/gasoline) have a shorter service life - they are something in between in terms of service life between traditional gasoline units and gas generators.

5. How is an inverter generator better than a conventional one?

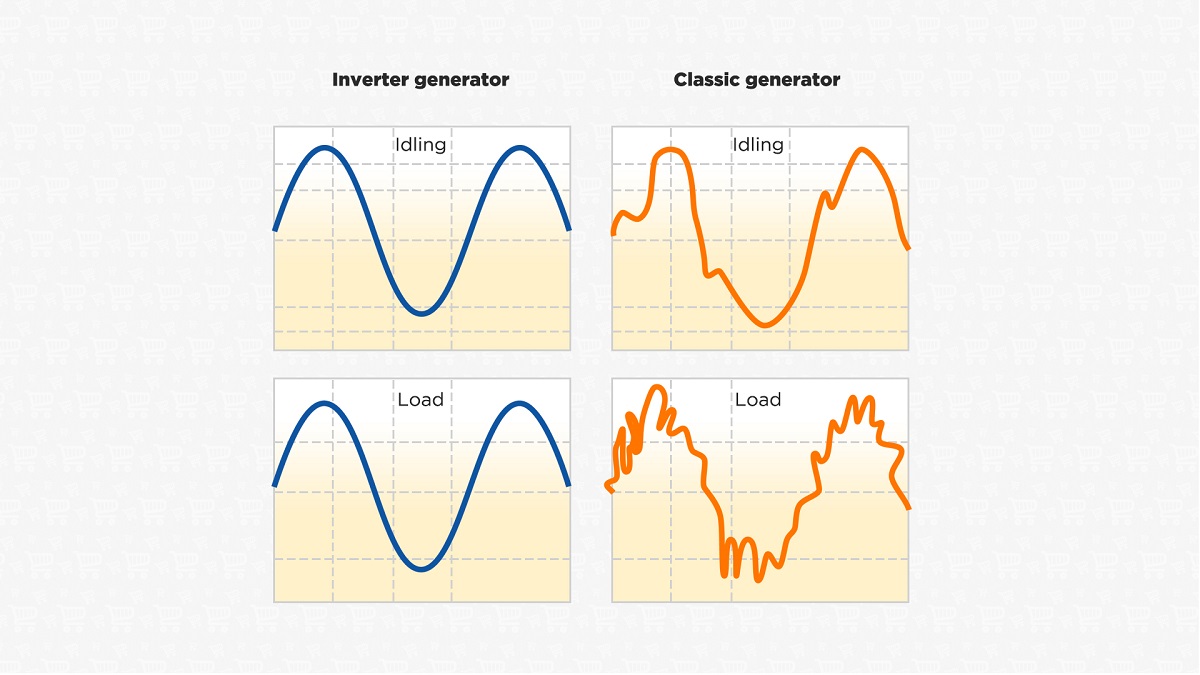

Inverter generators differ from traditional models by the presence in the circuit of an additional electronic unit, which ensures double conversion of the generated current: from alternating to direct, and then again to alternating. The inverter microprocessor stabilizes the oscillations of electrical waves and at the output we obtain a pure voltage of the correct sinusoidal shape. It corresponds as closely as possible to the parameters of conventional AC networks (as in a socket).

Generators with this output signal form can be used to power almost any type of load, incl. delicate electronics that place high demands on the quality of the input voltage. This could be heating boiler control equipment, computers and laptops, various audio equipment, etc.

Other advantages of models with an inverter alternator include flexible adjustment of engine operation depending on the connected load, low noise and fuel efficiency. And in general, inverter generators have more compact dimensions compared to their traditional counterparts. But their acquisition will cost more.

6. How can a gasoline generator be converted into a gas generator?

Almost any gas generator can be converted to run on natural gas. In addition to saving money on fuel, this solution is more environmentally friendly and will help extend the life of the generator. To do this, you will need to buy a universal gas kit (UGK) and a special reducer that will control the permissible pressure level in the gas line.

The gas conversion kit is installed instead of the standard carburetor, and you can handle its installation yourself. All you need is a plumbing tool and more or less straight hands. The UGK is selected for the specific power of the generator, and step-by-step instructions for its installation are usually included out of the box.

7. What gas do gas generators operate on?

One of the significant advantages of gas generators is the ability to operate on natural (main) gas. When stationary, they can be connected to the centralized gas supply network. In fact, this allows you to obtain a relatively inexpensive source of electricity that does not require constant refueling.

The second option is liquefied (ballooned) propane-butane gas. In this case, you just need to get a gas cylinder and refill it periodically. Note that the difference between these options lies in the design of the reducer, which stabilizes the gas pressure and supplies it to the carburetor with the parameters necessary for normal operation.

8. Is it possible to use a gas generator indoors?

The only correct answer to this question is a categorical no! It is not allowed to operate a gas generator either in an apartment or in the closet of a private house. The only exceptions to the rule are specially adapted generator outbuildings, where proper ventilation is provided and there is a well-thought-out system for removing exhaust gases.

With certain reservations, gas generators manage to be used on the constantly open balconies of apartment buildings. Inverter generators with a soundproofing casing and vibration-absorbing pads are suitable for this - they make less noise and are safer to use. But still, the noise from the generator’s operation is unlikely to be appreciated by neighbors, and venting exhaust gases out the window is also not the best option.

9. Is it possible to use the generator at subzero temperatures?

The generator can be used year-round, incl. at sub-zero ambient temperatures. It is only important to use low-viscosity motor oils that remain fluid in the cold, monitor the battery charge level in models with an electric starter, and in the case of diesel generators, fill in winter grades of diesel fuel. Summer diesel fuel thickens at low temperatures and is not pumped freely through the system.

Optionally, some models of diesel generators have built-in engine heating systems. And remember the main thing - the power unit will not be able to produce full power until the required temperature conditions are established in it. Therefore, you need to let the generator idle for a while before connecting the load.

Gas generators are most resistant to negative temperatures. However, it must be taken into account that in cold weather the gas pressure in the cylinders may decrease - make sure that the fuel supply system is working correctly.

10. Is it possible to connect a welding machine to the generator?

Specialized welding generators are specially designed for welding - the electrodes can be connected to them directly and work can be carried out outside the area of access to the power grid. If we consider traditional generators, models of sufficient power with a synchronous alternator are suitable for welding - they optimally withstand increased starting currents and cope well with high loads in long-term operation.

Based on the diameter of the electrodes used, it is proposed to select generators of the following powers:

- 2 mm - 2.5 kW;

- 3 mm - 3.5 kW;

- 4 mm - 4.5 kW.

As for inverter welding machines and semi-automatic inverters, the appropriate inverter generators that are capable of producing a stable voltage of a pure sinusoidal shape are optimal for them.

Articles, reviews, useful tips

All materials