Gorilla Glass protection and the difference between its generations

The first iPhone was pompously presented at the very dawn of 2007. The smartphone has created a real revolution and set a completely new vector for the development of the mobile industry. However, in the iPhone prototype, a regular plastic screen was installed. The head of Apple, Steve Jobs, noticed that the display of the device was badly scratched, lying in a pocket with keys and other small things. It was less than six months before release...

In this short time, a glass screen was created for the first iPhone with the support of Corning. The company has been experimenting with chemical treatment of glass surfaces as far back as 1959 (Project Muscle). For unknown reasons, the project was frozen and revived by a specialist due to the insistence of Steve Jobs. The result of the collaboration between Apple and Corning was the tempered Gorilla Glass, which is now used in mobile devices everywhere.

How Gorilla Glass is Made

The basis of the production of Gorilla Glass is silicon dioxide, reinforced with additives from the limestone fraction and sodium carbonate. The resulting mixture is melted in a furnace at a temperature of about 1000 ° C, resulting in the formation of aluminosilicate glass. The molten mass is placed in a bath with tin - the glass floats on its surface due to the difference in the density of the materials, while all the heavy elements settle to the bottom of the bath. The surface in contact with tin is incredibly smooth. At the output, polished sheets of aluminosilicate glass are created.

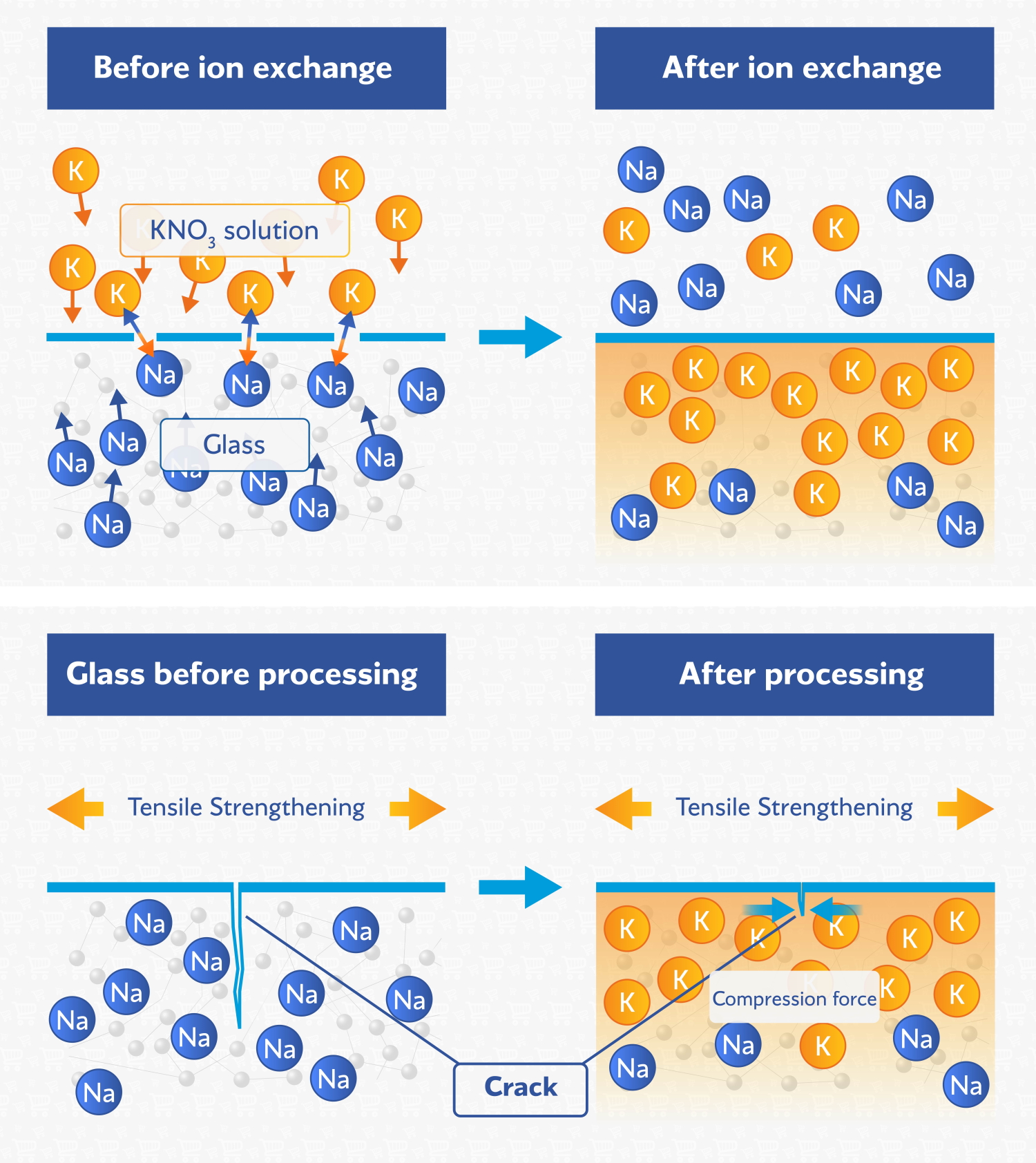

|

| Visual principles of glass processing and ion exchange procedures during hardening. |

Next, the glass must be tempered at a temperature of about 400 ° C. Finished sheets are passed through a bath of molten potassium salts. During hardening, small sodium ions are replaced by large potassium ions, which, when cooled, create a denser structure of the glass sheet. As a result, glass has high strength and does not lose its flexibility. Another significant advantage of ion exchange is the improved resistance of the glass to thermal expansion.

Gorilla Glass v1

The first generation of Gorilla Glass appeared in 2007. The glass was 1.5 mm thick and had an oleophobic coating to protect the display surface from fingerprints and greasy stains. According to the Mohs scale, the hardness of first edition Gorilla Glass is 6-6.5 units, while most metal alloys have a hardness of 5-5.5 units. Such glass can be harmed by grains of sand (quartz is higher in the Mohs scale in terms of hardness), topaz, corundum and diamonds (the last trio is extremely rare in everyday life).

In addition to the iPhone, Gorilla Glass v1 was also used in other smartphones. In total, there were about 250 such models.

Gorilla Glass v2

The second version of Gorilla Glass was forged for almost 5 years. It was introduced at the CES (Consumer Electronics Show) at the very beginning of 2012. The glass remains the same scratch-resistant, and its thickness has been reduced by about 20%. In laboratory tests, the second edition of Gorilla Glass withstood pressures up to 50 kg without the risk of being broken or cracked.

|

| The second edition of Gorilla Glass was presented at CES 2012. |

Thanks to the reduction in the thickness of the glass, Gorilla Glass v2 began to be used in in smartphones even more widely. The optical properties of the displays have also improved, in particular, the brightness indicators. And touchscreens have become more sensitive to touch.

Gorilla Glass v3

Gorilla Glass v3 was launched in 2013 with a new manufacturing process using Native Damage Resistance technology to increase durability. Henceforth, Gorilla Glass began to withstand pressure up to 150 kg, and their scratch resistance increased by a good third (about 35%). The glass thickness was 0.8 mm.

Despite the "venerable age", the third generation of Gorilla Glass is still in demand. All because of the high scratch resistance - it was possible to surpass this indicator only 7 years later in the Victus version.

Gorilla Glass v4

Smartphone screens are most damaged when dropped on a hard surface. The attention was focused on this exact factor during the development of the fourth edition of Gorilla Glass, released in 2014. In lab testing, v4 glass is twice as strong as previous generations. In parallel, Corning engineers reduced the glass thickness to 0.4 mm.

|

| One of the test benches where strength tests of Gorilla Glass are carried out. |

Increasing the resistance of glass to impacts has saved the lives of so many screens. And this parameter was improved in the next version of Gorilla Glass even more.

Gorilla Glass v5

The v5 glass is four times more impact resistant than its predecessor. It is promised that in about 80% of cases when a smartphone falls on hard surfaces from a height of 1 m, the gadget's display will remain unharmed. Moreover, good chances of maintaining the integrity of the screen are preserved even when falling from a 1.6-meter height.

The thickness of the glass Gorilla Glass v5 remained the same - 0.4 mm. This version of protective glass was used everywhere.

Gorilla Glass v6

The sixth version of Gorilla Glass was introduced in mid-summer 2018. A distinctive feature of it was the resistance to repeated falls on hard uneven surfaces. Glass v6 can withstand up to 15 drops in a row from a height of 1 m. Initially, flagship smartphones were equipped with such glass, but then the technology spread to medium-level devices.

Gorilla Glass Victus / Victus+

Corning abandoned digital generation numbering in 2020, when they released Gorilla Glass Victus to replace the v6 version. It guarantees to endure single drops from a height of up to 2 m, as well as up to 20 consecutive drops from a height of 1 m. In terms of scratch resistance, the Victus edition is twice as superior to its predecessor v6 and bypassed the non-replaceable leader v3.

|

| Gorilla Glass Victus and Victus + are rightfully considered one of the most durable. |

There is also an improved modification of the protective Gorilla Glass Victus - with an additional "plus" postfix. In terms of scratch resistance, it is as close as possible to ceramics. According to the Mohs mineralogical hardness scale, the glass starts to scratch at 7/10, while the original Victus scratches at 6/10. Victus+ glass is finally safe from dangers of grains of sand.

Gorilla Glass Victus 2

Towards the end of 2022, the announcement of the next generation - Gorilla Glass Victus 2 took place. It took the weight gain and increase in the dimensions of modern smartphones into account, and also put emphasis on providing the best protection when the gadget falls on concrete surfaces. Screens under cover of Victus 2 glass are not afraid of falling from a height of 1 m onto a concrete floor.

In other parameters, the protective glass has retained the specs of the previous edition - it still withstands up to 20 consecutive drops on hard surfaces from a meter height and single drops from a height of 2 m onto asphalt. Gorilla Glass Victus 2 is expected in the top tier mobile devices.

Gorilla Glass SR+

For the safety of wearable electronics, in particular, smartwatches, in 2016 Corning released Gorilla Glass SR +. It implemented the Project Phire technology, which is a kind of hybrid between traditional "gorilla" and sapphire glasses. The numbers say that the SR+ coating is about 70% stronger and 25% less glare compared to analogues used to protect the watch faces of wearable gadgets.

Gorilla Glass SR+ made its debut aboard the Samsung Gear S3 smartwatch. The glass-composite material can withstand shocks, bumps and scratches from clothing while maintaining optical transparency and touch sensitivity.

Gorilla Glass DX / DX+

In 2018, SR+ was replaced by two generations of tempered Gorilla Glass DX and DX+. They are originally designed to nullify sun glare and improve screen readability on wearable gadgets in direct sunlight. Also, these protective glasses protect the screen surface from scratches and impact damage.

|

| From the screens of smartwatches and fitness trackers, Gorilla Glass DX and DX + protective glasses migrated to smartphone camera lenses. |

After some time, DX and DX + glass lenses were adapted for use in protecting lenses in smartphone cameras. The glass composite was redesigned to provide high scratch resistance and improve light transmission (up to 98% of light passes through glass).

Alternatives

Suitable alternatives to "gorilla" protective glasses can be counted on the fingers of one hand. The most popular products of the Japanese company Asahi Glass - aluminosilicate glass Dragontrail. Their production process involves sending liquid glass blanks to a furnace with molten tin and adding particles to strengthen the material, after which the glass is quickly cooled and sent for cutting. Dragontrail X coatings are most often found in Chinese smartphones from the low and mid-price segments, while Pro modifications are on smartphones of a strong medium level.

|

| Asahi Glass produces both regular Dragontrail glasses for smartphone screens and replaceable tempered glass screen protectors. |

Other competitors to Gorilla Glass found even less popularity. These are products of Schott AG and its Xensation glass, as well as Nippon Electric Glass with Dinorex glass.

Are sapphire crystals not a panacea?

On the aforementioned Mohs scale, sapphire crystals are almost at the very top - only diamonds are placed above. This means that such coatings are very difficult to scratch. However, with point impacts, the sapphire immediately shatters into small fragments. As a protective coating for displays, the use of this material is impractical, with the exception of wearable electronics and smartphone cameras. Sapphire crystals also have other disadvantages: worse light transmission and high cost of production. Due to these factors, even smartwatches are increasingly ditching sapphire glass in favor of Gorilla Glass.

_____

Corning's monopoly in the tempered glass industry is getting stronger every year. Preference should be given to devices with Gorilla Glass as a protective coating for surfaces, since there are practically no prominent alternatives to “gorilla” products in general use.

Articles, reviews, useful tips

All materials