IPS, LTPS, P-OLED or AMOLED? Understanding the main types of displays in portable technology

Differences between IPS and AMOLED matrices

Portable technology has recently been dominated by 2 types of matrices ― IPS and AMOLED. The Internet has divided into several warring camps. In the first, they drown for IPS displays and mercilessly criticize AMOLED for excessive colour and acidity. In the sect of flagship witnesses, on the contrary, they are sure that only an AMOLED or super AMOLED display should stand in a good phone, and everything else is just economy. In the question "IPS or AMOLED", the truth, as usual, is in the middle and each type of matrix has its well-known advantages and disadvantages.

|

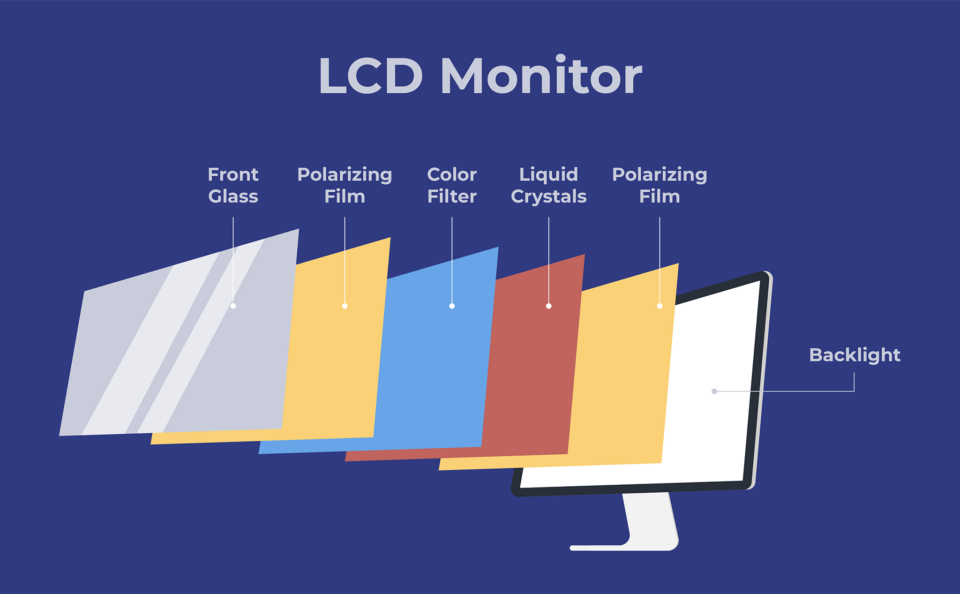

An in-plane switching matrix (or simply IPS) is an advanced variation of a conventional liquid crystal display, but with a smoother and brighter LED backlight. The strengths of IPS-matrices are natural colour reproduction with wide viewing angles, seasoned with an increased service life of LEDs and the availability of such matrices. At the same time, they do not have the most impressive contrast, and the black colour lacks depth. Due to the narrow range of illumination IPS screens (especially inexpensive) they do not know how to separate the brightest and darkest pixels well, so this screen does not correctly display the depth of black and shades of grey.

On the contrary, AMOLED matrices have no competitors when it comes to maximum brightness, contrast, colour rendering and black depth. Thanks to the use of organic AMOLED LEDs, the display does not need to additionally highlight black pixels, so it consumes battery resources more economically. The flip side of the coin is problems with white balance, as well as often excessive contrast and colour saturation, as if all the display settings were turned off by 100%. To a greater extent, this applies to smartphones near the top for $ 400 – 500, which strive for the stars, but are forced to save on something.

If you make a direct comparison between devices with AMOLED and IPS displays of the same resolution, you will notice that the brightness, dynamic range and contrast are on the OLED side. Fonts look clearer, sharper and better drawn on such matrices. And regardless of the brightness of the backlight and shades. On the other hand, IPS has better background areas, soft transitions look more distinct and brighter.

Evolution of AMOLED screens in portable technology

|

The principle of using AMOLED technology (Active Matrix Organic Light Emitting Diode) is the use of organic LEDs and an active matrix with independent LEDs that are illuminated and coloured individually. In fact, AMOLED is a kind of OLED display with an active matrix. Hence the name: AM in the word AMOLED means Active Matrix.

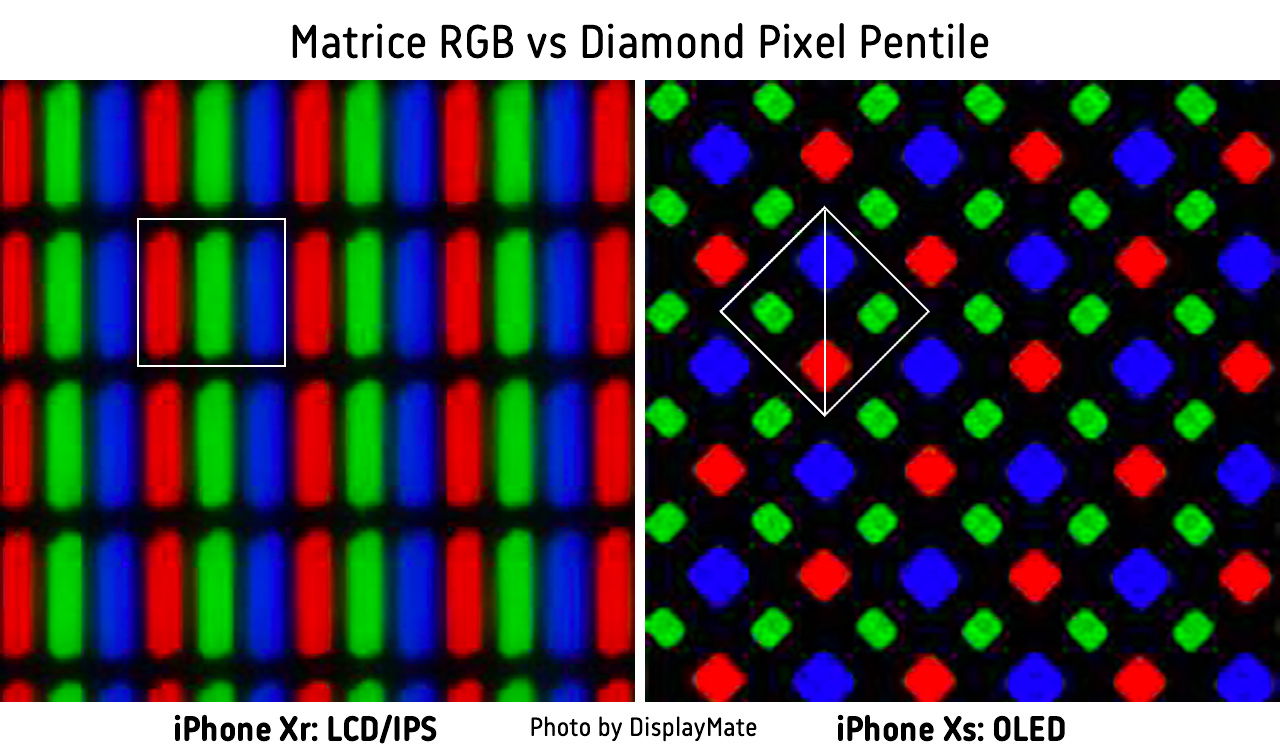

Super AMOLED is a Samsung development in which the touch layer is embedded directly into the matrix, and is not superimposed on top of it using an air cushion. In addition, Samsung decided to change the matrix structure by reducing the number of blue subpixels. Because of this, the actual display resolution is lower than the stated one, and the picture may seem grainy.

|

Super AMOLED Plus has become a bug fix. Samsung engineers abandoned the PenTile RGBG matrix structure in favor of the usual Real-Stripe technology. To form 1 pixel, 12 sub-pixels are now used instead of 8, so that the image is clearer and more contrasting.

Dynamic AMOLED is the pinnacle of technical thought in the development of displays (at least for now). All the rakes of AMOLED matrices were hidden away in the barn, and instead they increased the peak brightness/contrast indicators and screwed the ability to display 100% of the DCI-P3 colour spectrum. Thanks to this, a Dynamic AMOLED display can fully display all the charms of HDR content.

As you can see, along this chain, you can trace the entire evolution of screens with an active matrix and better understand whether a regular smartphone with AMOLED is suitable for you or it is better to fork out for a full-fledged Dynamic AMOLED.

Features of the PLS matrix in smartphones

|

PLS (Plane To Line Switching) is a kind of IPS matrices manufactured by Samsung, which the Korean giant is actively implementing in its televisions, smartphones and monitors. From a technical point of view, the difference between IPS and PLS screens consists in the structure of the control electrodes: IPS has them in one plane, and PLS has two such planes. This made it possible to accelerate the reorientation of liquid crystals, reducing the response time of the display.

In fact, the difference between PLS and IPS matrices is minimal and most people will not be able to distinguish them from each other in a blind test. In this case, the question arises, why did Samsung make this mess? There are several reasons for this. The first is purely economic. IPS-matrices were invented by Hitachi, so it is free to dictate its financial terms to other manufacturers. From this point of view, PLS is the same IPS, but cheaper.

The second reason is the speed of reaction and responsiveness. PLS matrices have a response rate of 4 ms versus 12 ms for IPS, so flickering on them is not so noticeable. Especially when the smartphone display has the refresh rate increased to 90 or 120 Hz. Also, due to the removal of half of the control electrodes on the second plane of the display, PLS screens have a higher pixel density, so from a technical point of view, a PLS display with a resolution of 2K/4K is easier to make than IPS.

Samsung is actively experimenting with PLS matrices in TVs and monitors, but recently such displays have flooded into the smartphone market in large numbers. Popular low-cost devices like Samsung Galaxy M12, Galaxy A21s and Galaxy A01 are built on the basis of PLS screens.

OLED vs P-OLED

|

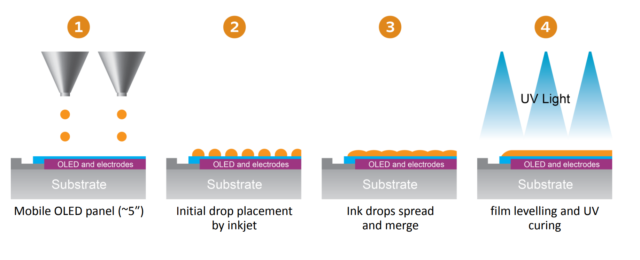

Like conventional liquid crystal LED displays, OLED screens are based on the same principle of electroluminescence, when a current is applied to a semiconductor to make it glow. The difference is that LED lamps use inorganic semiconductors like silicon, which transmit light through themselves. OLED uses organic substances that can be applied to the surface in the thinnest layers, like paint. And they themselves are sources of light.

There is often an opinion on the web that OLED displays will turn out the same revolution in the display market that LCD displays once staged. They have impeccable viewing angles, a wide colour palette, record response time and an impressive depth of black. Thanks to the individual pixel illumination, OLED displays save battery power, since they do not need to waste energy on highlighting dark and black pixels. The problem is that making OLED displays is not a cheap pleasure at all. Therefore, they are found only in really expensive smartphones of the iPhone 12 Pro Max, Google Pixel 5 or Huawei P40 Pro level.

|

To reduce the cost of production, LG engineers decided to replace expensive glass substrates with plastic. But not simple, but a special polymer plastic, which is characterized by increased flexibility and resistance to high temperatures. In search of a way to save money, LG unexpectedly opened a Pandora's box called a "bendable screen", and P-OLED displays in the future may become the basis for paper-thin televisions, flexible smartphones, e-paper, smart clothes, etc.

The first LG device with a P-OLED display was the LG G Flex smartphone, followed by the Flex 2 and a pack of LG Watch smartwatches. Due to licensing features, this standard will not unfold in its entirety, so major brands are either trying to figure out the formula for an perfect polymer OLED display on their own, or trying to adapt these developments in existing displays. For example, the Motorola Razr 2019 has a flexible G-OLED display, and Samsung is testing the capabilities of hybrid Dynamic AMOLED matrices in Fold smartphones.

LTPS displays in tablets and laptops

|

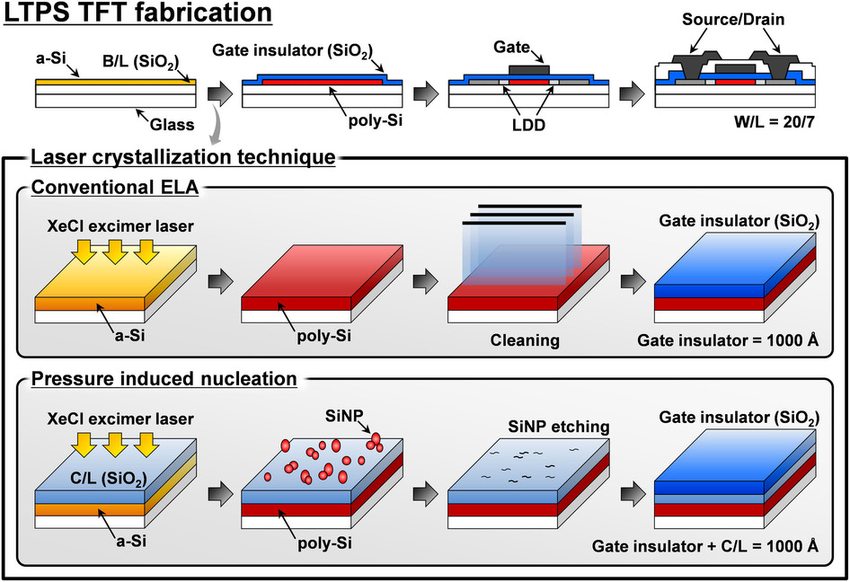

Many people probably had to meet the LTPS display in a smartphone, but not everyone can answer what it is and how it is better (or worse) than other types of matrices. In fact, this is an IPS display add-on with improved responsiveness. As a basis, both types of displays use transistors based on amorphous silicon (a-Si). It is a cold-resistant substance, the operating temperature of which is 200 degrees. It is easy to handle and it conducts current perfectly. The problem is that this material has low electron mobility, so conventional IPS matrices are often called slow.

LTPS screen solves this problem by changing the production process. Amorphous silicon is converted into polycrystalline form using an excimer laser, which operates at relatively low temperatures, so it cannot damage the glass substrate of the screen. Otherwise, IPS and LTPS screens have a similar scheme of using filters, LEDs and liquid crystals. Therefore, the properties of both types are almost identical in most cases. It's just that the LTPS display is more responsive and slightly more expensive to produce.

Articles, reviews, useful tips

All materials